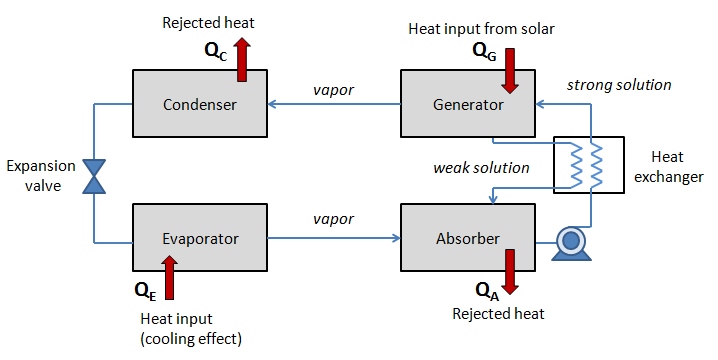

Fluid gas absorption cycle uses the principle of partial pressure between two fluids to create the cooling effect. The original design of an absorption chiller is credited to the likes of Ferdinand Carré Carl Munters and Baltzar Von Platen renowned scientists who did their works between the 1850s and 1920s. Absorption cooling system design

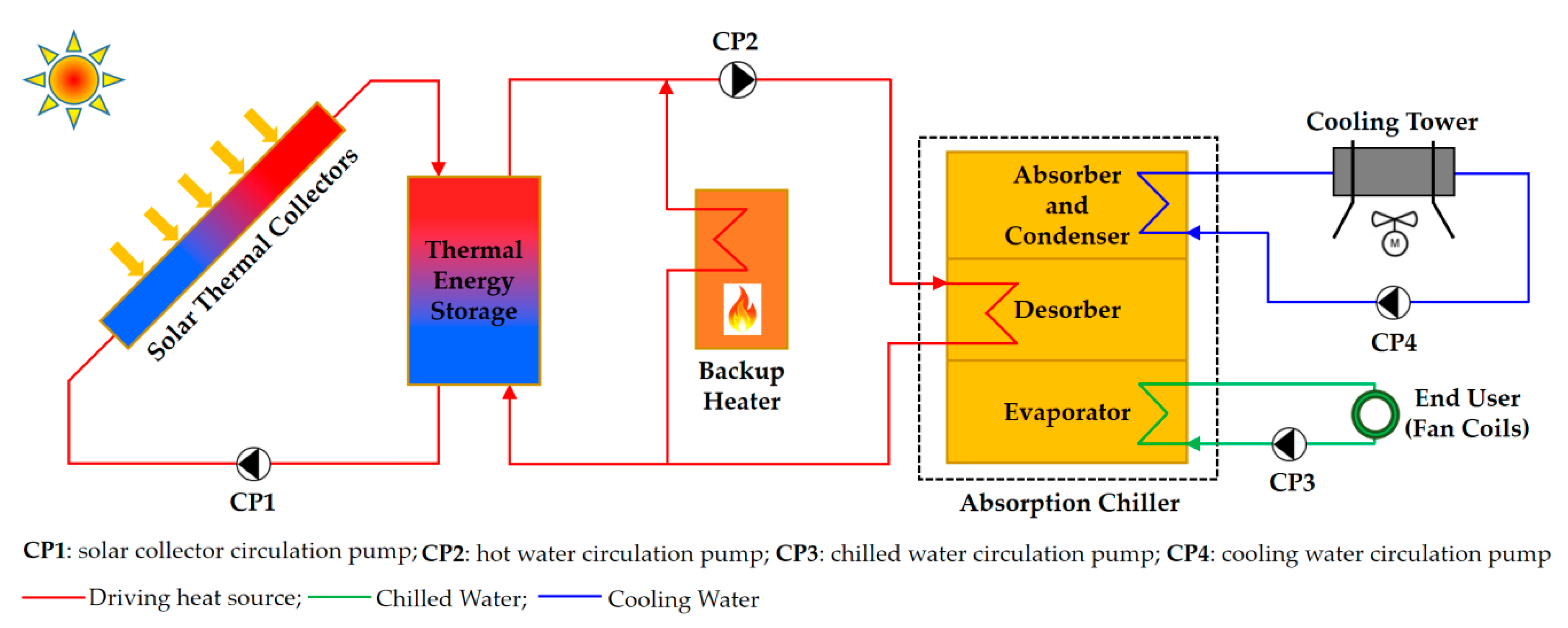

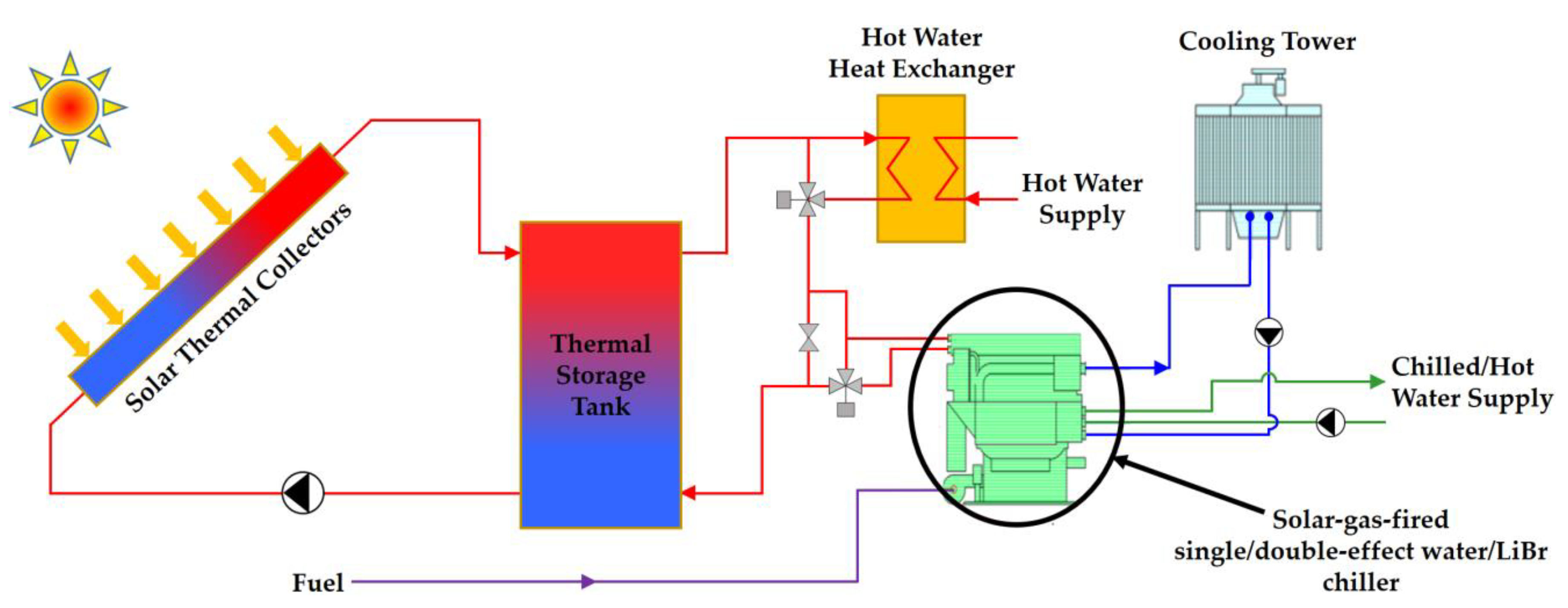

Absorption Cooling System Design, The schematic diagram shows the proposed absorption air conditioning system in the truck. While the products were first produced commercially in 1923 it was only in the 60s that serious production started due to rising demand for caravan. Over the years the absorption solution has become preferable by many than an electric chiller. There is also a heat exchanger to improve the efficiency of the system.

Basics For Absorption Chillers 2009 03 01 Engineered Systems Magazine From esmagazine.com

Basics For Absorption Chillers 2009 03 01 Engineered Systems Magazine From esmagazine.com

Cooling load the absorption system is designed. Extensive analysis of the thermodynamics heat transfer and chemical properties of a three fluid gas absorption system was conducted to design and construct the structural model shown in the report. Absorption cooling system Ammonia water. Until recently the absorption cooling technology was not readily available for small capacity applications and was quite expensive compared to the traditional vapor compression cooling technology.

Heat exchanger sizing are made based on type of heat exchanger used.

Read another article:

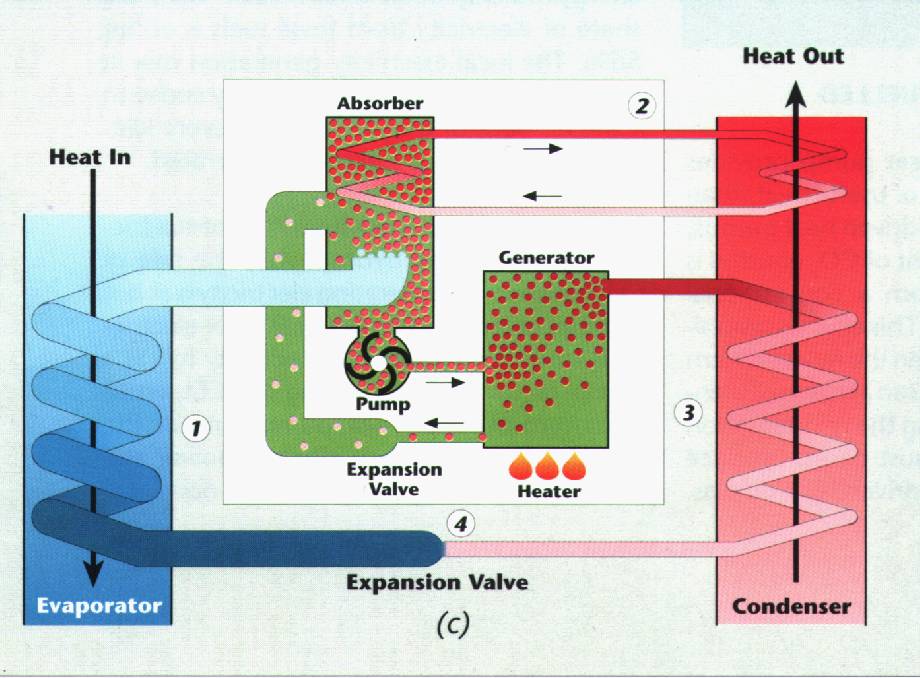

1- Air-Cooled Absorption Single Effect. Fluid gas absorption cycle uses the principle of partial pressure between two fluids to create the cooling effect. It is the most popular choice in absorption cooling. The Rankine engine vapor compression and the absorption cooling units operate on the basis of closed cycles-fixed amounts of working fluid are circulated within sealed equipment. The evaporator and absorber comprise the bottom most chamber.

Source: e-education.psu.edu

Source: e-education.psu.edu

Extensive analysis of the thermodynamics heat transfer and chemical properties of a three fluid gas absorption system was conducted to design and construct the structural model shown in the report. A domestic-scale prototype experimental solar cooling system has been developed based on a LiBrH2O absorption system and tested during the 2007 summer and autumn months in. When selecting chiller types and numbers The following factors shall considered. The objective of this work is to design and construct a lithium bromidewater LiBr-H 2 O absorption cooling system with a nominal capacity of approximately 1. 8 2 Absorption Cooling Eme 811 Solar Thermal Energy For Utilities And Industry.

Source: goenergylink.com

Source: goenergylink.com

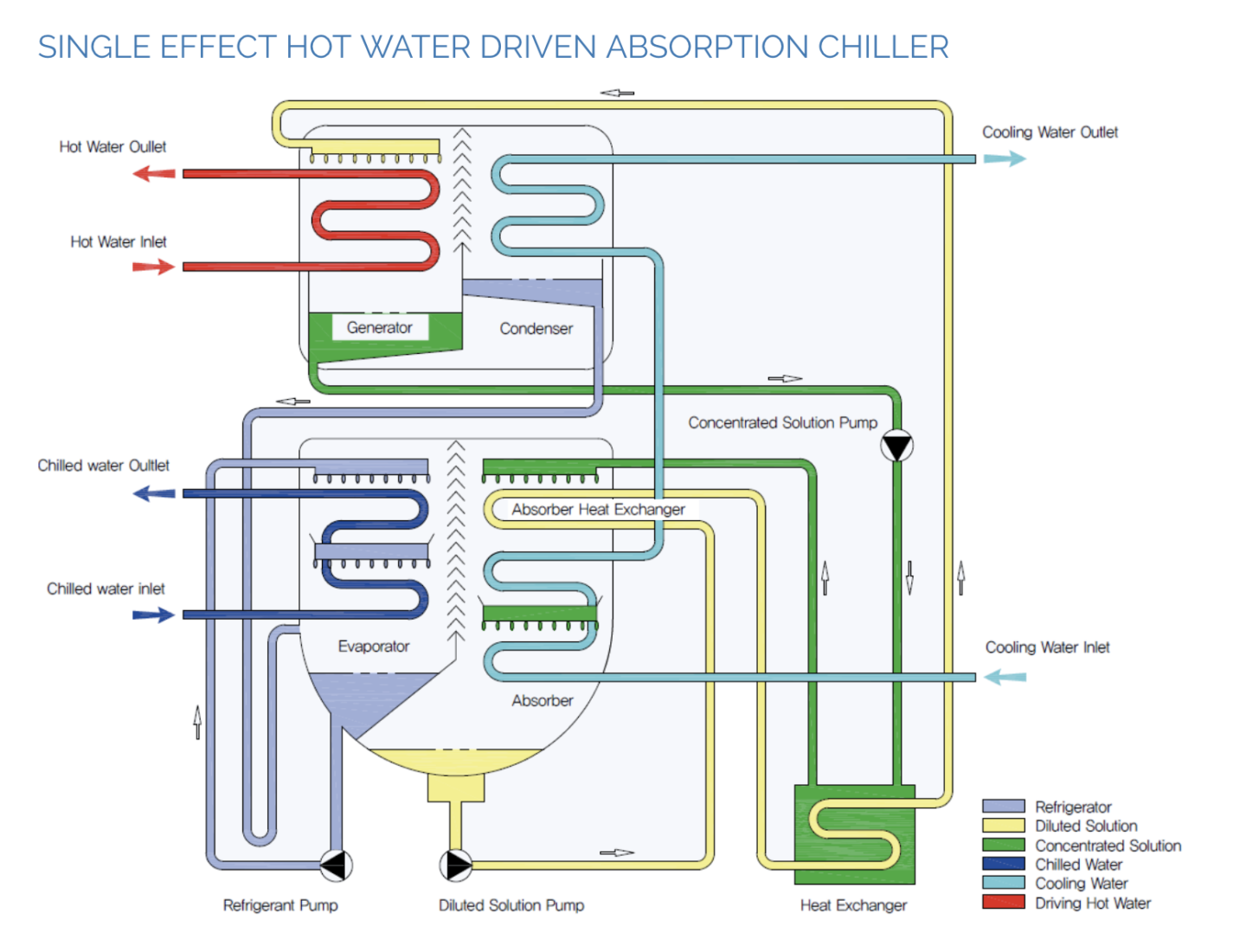

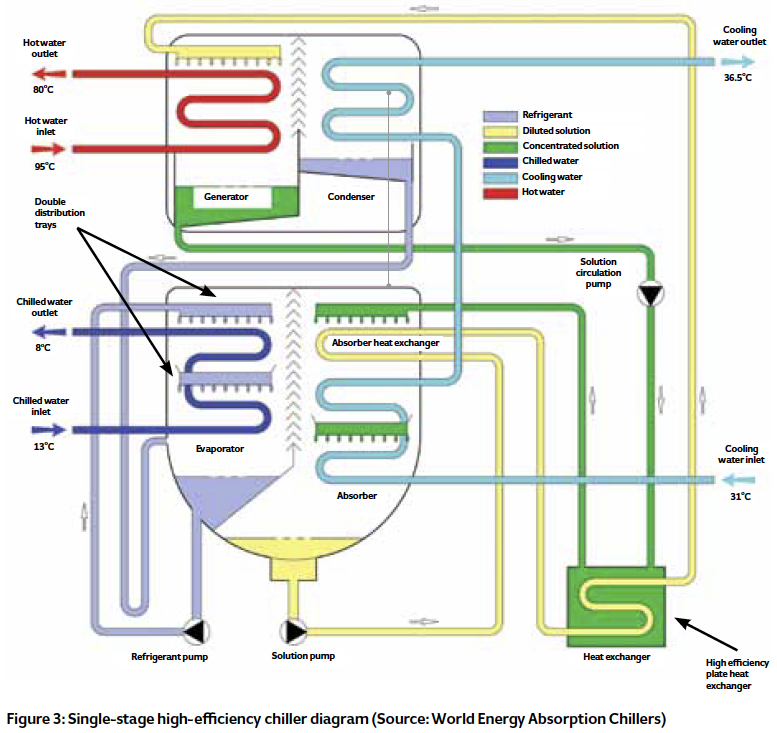

The design of these systems involves the choice of the main components their sizing and an adequate control strategy of the whole. The single-effect absorption cooling system SEACS is one of the first designed kind of ACSs. The double-effect absorption cooling system DEACS is a design development of a single-effect cooling system to achieve more useful output. The exhaust Strong solution. How Absorption Chillers Work Energylink.

Source: sciencedirect.com

Source: sciencedirect.com

As shown in Fig. Schematic diagram of proposed arrangement of vapour absorption air conditioning system in truck The exhaust heat is utilized by using the heat exchanger in the generator. Desiccant cooling systems on the other hand may be designed for open-. SEACSs are generally designed with six main components. Absorption Cooling An Overview Sciencedirect Topics.

Source: mdpi.com

Source: mdpi.com

The schematic diagram shows the proposed absorption air conditioning system in the truck. Their size is large and complex it needs constant maintenance its efficiency is. In view of this current paper presents a simulation study to describe energy saving potential of a solar biogas and electric heater powered hybrid vapor absorption chiller VAC. At the beginning these machines were used to make ice and cool food. Applied Sciences Free Full Text New Developments And Progress In Absorption Chillers For Solar Cooling Applications Html.

Source: mdpi.com

Source: mdpi.com

Using dramatic illustrations the Note explains the principle of absorption cooling and the components of absorption chillers. Using dramatic illustrations the Note explains the principle of absorption cooling and the components of absorption chillers. Components like absorber evaporator condenser and generator are designed based on capacity 2 kW. 2 The possibility of working at a low generation temperature and a pressure of 70C - 80C 4 - 8 kpa respectively with a coefficient of performance COP 04 - 08 during the summer months in. Applied Sciences Free Full Text New Developments And Progress In Absorption Chillers For Solar Cooling Applications Html.

Source: goldman.com.au

Source: goldman.com.au

In absorption cooling the thermal energy from hot water or steam is. The objective of this work is to design and construct a lithium bromidewater LiBr-H 2 O absorption cooling system with a nominal capacity of approximately 1. 3- Absorption Double Effect Indirect-Fired. There is also a heat exchanger to improve the efficiency of the system. How Does An Absorption Chiller Work Goldman Energy.

Source: researchgate.net

Source: researchgate.net

The basic absorption cycle shown in. The system uses two coolants the first of which performs evaporative cooling and is then absorbed into the second coolant. Generator condenser absorber pump HEX and evaporator. Their size is large and complex it needs constant maintenance its efficiency is. Schematic Representation Of Single Stage Vapor Absorption Refrigeration Download Scientific Diagram.

Source: sciencedirect.com

Source: sciencedirect.com

Working principle of an Absorption chiller. The basic absorption cycle shown in. A small capacity vapor absorption system is first analyzed and characteristics at various points aremeasured. 1- Air-Cooled Absorption Single Effect. Absorption Refrigeration System An Overview Sciencedirect Topics.

Source: theengineeringmindset.com

Source: theengineeringmindset.com

Components like absorber evaporator condenser and generator are designed based on capacity 2 kW. The working fluids do not come in contact with the building air. The main components of the absorption chiller are the condenser and the generator which comprise the top most chamber. Over the years the absorption solution has become preferable by many than an electric chiller. Absorption Chiller How It Works The Engineering Mindset.

Source: instrumentationtools.com

Source: instrumentationtools.com

Heat exchanger sizing are made based on type of heat exchanger used. Until recently the absorption cooling technology was not readily available for small capacity applications and was quite expensive compared to the traditional vapor compression cooling technology. Through previous studies related to the design and selection of the absorption cycle system the recovery of waste heat from small sources such as automobile engines and its application in particular to absorption coolers is very rare for several reasons the most important of which are. Over the years the absorption solution has become preferable by many than an electric chiller. Hvac Double Effect Absorption Chiller Inst Tools.

Source: colibris.home.xs4all.nl

Source: colibris.home.xs4all.nl

It is the most popular choice in absorption cooling. An absorption refrigerator is a refrigerator that uses a heat source eg solar energy a fossil-fueled flame waste heat from factories or district heating systems to provide the energy needed to drive the cooling process. In air-conditioning strategy of decoupling cooling and ventilation tasks has stimulated considerable interest in radiant cooling systems with dedicated outdoor air system DOAS. 2 The possibility of working at a low generation temperature and a pressure of 70C - 80C 4 - 8 kpa respectively with a coefficient of performance COP 04 - 08 during the summer months in. Ammonia Absorption.

Source: goldman.com.au

Source: goldman.com.au

There is a wide range of available options for different working conditions. In absorption cooling the thermal energy from hot water or steam is. Absorption chiller may be classified to. The design of these systems involves the choice of the main components their sizing and an adequate control strategy of the whole. How Does An Absorption Chiller Work Goldman Energy.

Source: esmagazine.com

Source: esmagazine.com

Cooling load the absorption system is designed. The absorption refrigeration system is defined as a thermally driven refrigeration technology for exploiting the heat from low-grade energy sources for cooling purposes. A small capacity vapor absorption system is first analyzed and characteristics at various points aremeasured. While the products were first produced commercially in 1923 it was only in the 60s that serious production started due to rising demand for caravan. Basics For Absorption Chillers 2009 03 01 Engineered Systems Magazine.

Source: cibsejournal.com

Source: cibsejournal.com

4- Absorption Double Effect Direct-Fired. The original design of an absorption chiller is credited to the likes of Ferdinand Carré Carl Munters and Baltzar Von Platen renowned scientists who did their works between the 1850s and 1920s. It is the most popular choice in absorption cooling. A small capacity vapor absorption system is first analyzed and characteristics at various points aremeasured. Module 91 High Efficiency Waste Heat Powered Lithium Bromide Absorption Chillers Cibse Journal.

Source: theengineeringmindset.com

Source: theengineeringmindset.com

Using dramatic illustrations the Note explains the principle of absorption cooling and the components of absorption chillers. Their size is large and complex it needs constant maintenance its efficiency is. The absorption process is exothermic ie it generates heat and heat must be rejected from the absorber to the condenser water and cooling tower loop. An absorption cooling system is a system activated by heat to give a solution to the absorption process. Absorption Chiller How It Works The Engineering Mindset.