Amerden AGVS has a proven approach to the design and delivery of an AGV system. Although they appear similar the AGV and ASRS serve two separate purposes. Agv system design

Agv System Design, This document supersedes EN 15251997. HW Cheong and H. AGV System Parameters 200. Auto Guided Vehicle AGV Design.

Agv System Architecture Download Scientific Diagram From researchgate.net

Agv System Architecture Download Scientific Diagram From researchgate.net

AGVs-based Material Handling Systems MHSs are widely used in several Flexible Manufacturing Systems FMS installations. GRAN D T OTA L MIN 000 100 000 100 DISTANCE ET 300029 420431 720460 150015 210216 68970 429200 Assuming the orst possible dispatching decisions the. Also these vehicles can come equipped with. Box 217 7500 AE Enschede The Netherlands Accepted.

TIME PLANNING PERIOD AVAILABILITY FACTOR BLOCKING DELAY TOTAL LOADED TRAVEL TOTAL UNLOADED TRAVEL TOTAL LOADUNLOAD CYCLE.

Read another article:

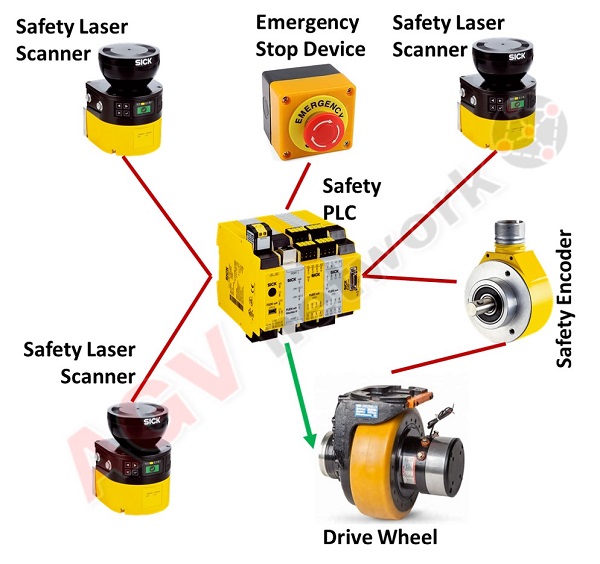

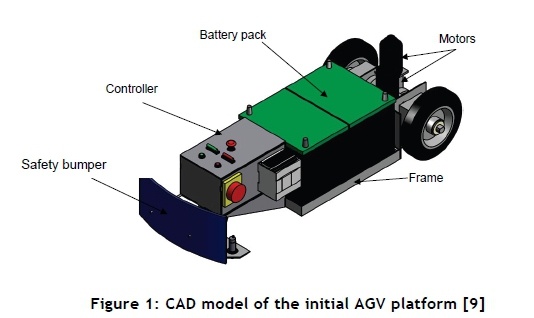

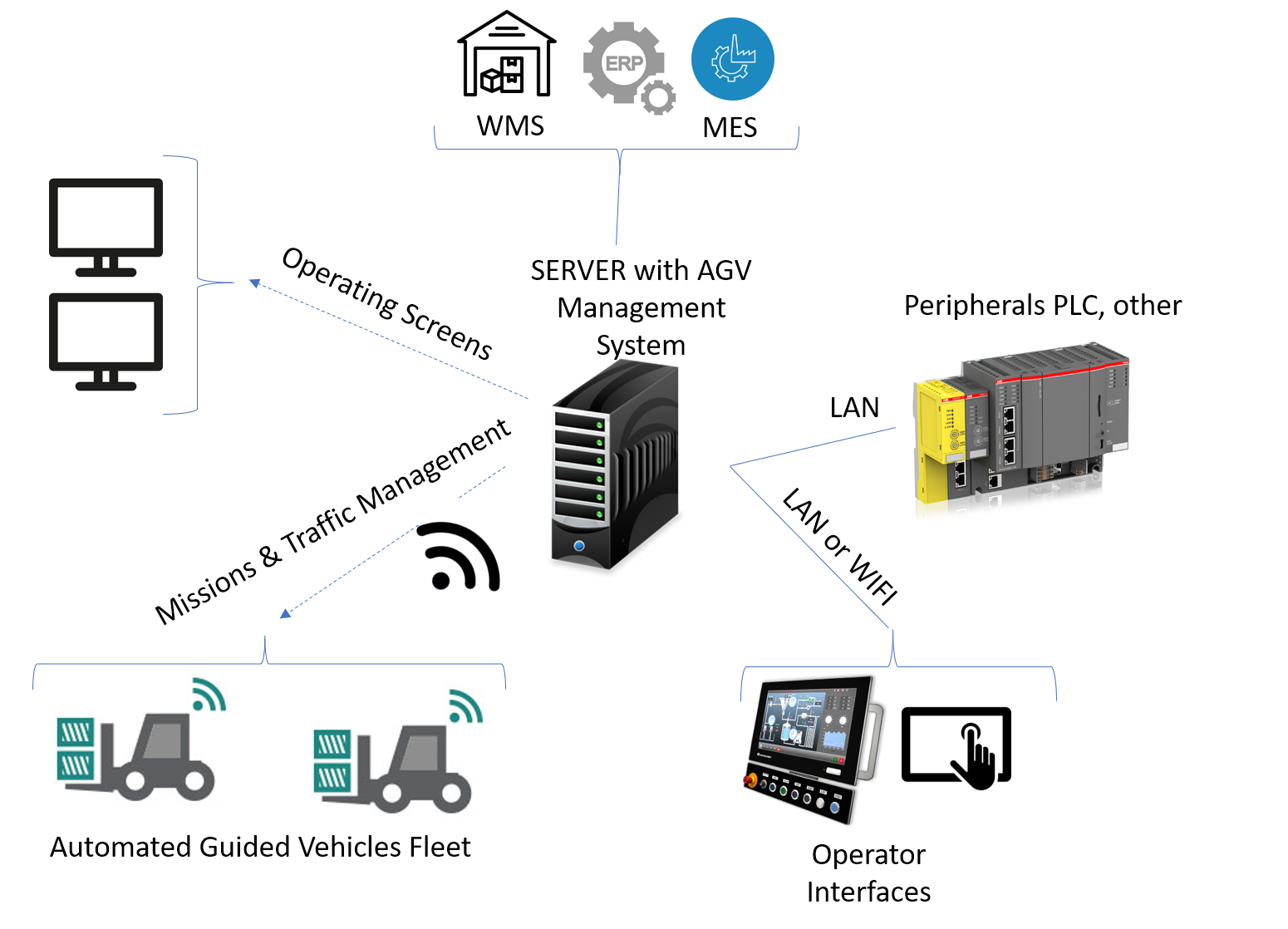

To broach these goals the Automated Guided Vehicle AGV was designed to collaborate with another autonomous vehicle the Automated Storage and Retrieval System ASRS. Once the material transport requirements are fully developed Amerden AGVS will design a system that delivers exactly the material handling transport and software functionality required. Besides AGV body with excellent performance will reduce the workload of daily maintenance and increases the service life of AGV system. Driverless industrial trucks and their systems. In order to improve the AGVs system efficiency and reliability both Siemens PLC and RFID technologies are applied for the design.

Source: semanticscholar.org

Source: semanticscholar.org

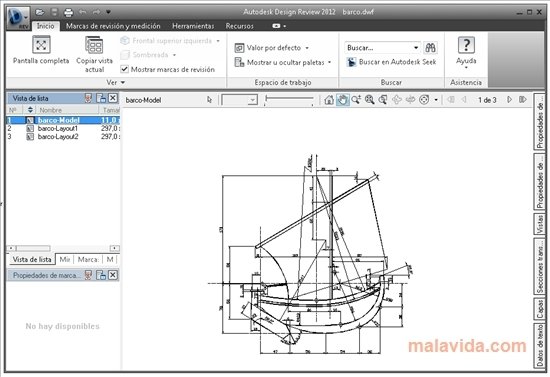

MAX AGV Control System with optimized priority traffic control and flexibility in the quantity and type of AGV stations and cargo handling. Besides AGV body with excellent performance will reduce the workload of daily maintenance and increases the service life of AGV system. 222 AGV System 6 223 Description of an AGV System 7 224 Components of an AGV System 8 225 AGV System Design 9 226 Flow Path Types 11 227 Language 15 CHAPTER 3 METHODOLOGY 31 Introduction 16 32 Project Flow Chart 16 33 Development of Control System for AGV 19 331 Development of AGV Circuit 19. This provides users with visual understanding of how their system is designed and how it will operate in their facility before they make new system purchase decision and. Design And Modeling Of Automated Guided Vehicle Systems Using Arduino Semantic Scholar.

Source: researchgate.net

Source: researchgate.net

AGVs-based Material Handling Systems MHSs are widely used in several Flexible Manufacturing Systems FMS installations. SYSTEM DESIGN As shown in Fig. The main objective of this. This provides users with visual understanding of how their system is designed and how it will operate in their facility before they make new system purchase decision and. The Architecture Of The Agv Transportation System Download Scientific Diagram.

Source: agvnetwork.com

Source: agvnetwork.com

Box 217 7500 AE Enschede The Netherlands Accepted. Landeweerd Production and Operations Management Group Department of Mechanical Engineering University of Twente PO. Driverless industrial trucks and their systems. America In Motion is your one stop shop for custom AGV systems. Understanding Agv Safety Systems Standards Sensors Rules What S Important To Know.

Source: handling.com

Source: handling.com

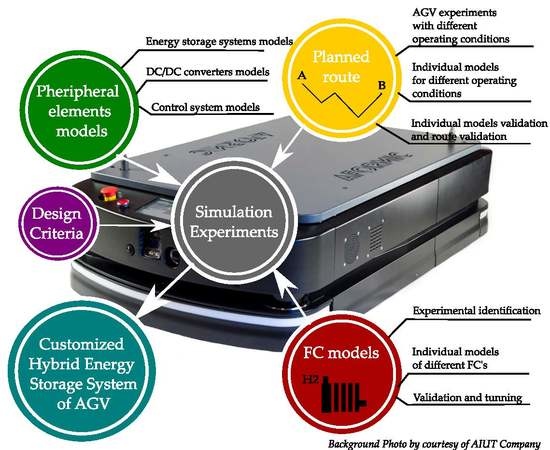

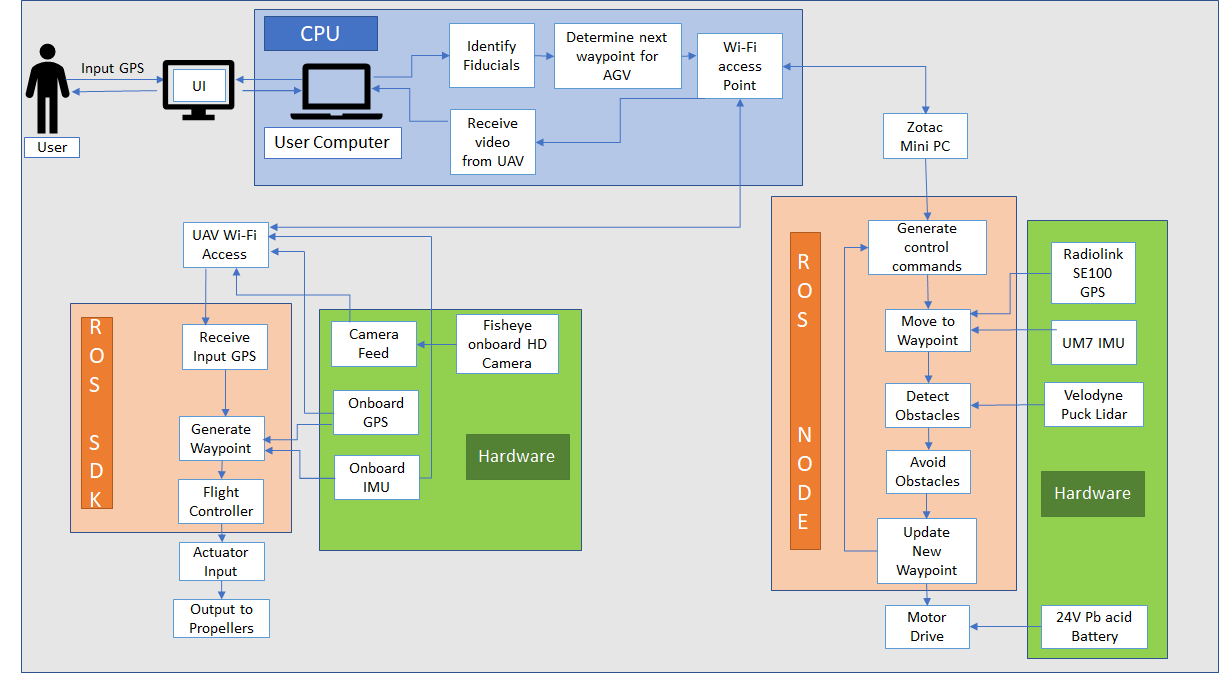

Because they move on a predictable path with precisely controlled acceleration and deceleration and include. Lee Procedia Computer Science 00 2018 000â000 Fig. AGV System Parameters 200. To broach these goals the Automated Guided Vehicle AGV was designed to collaborate with another autonomous vehicle the Automated Storage and Retrieval System ASRS. Autonomous Guided Vehicle Block Diagram.

Source: mdpi.com

Source: mdpi.com

America In Motion is your one stop shop for custom AGV systems. This provides users with visual understanding of how their system is designed and how it will operate in their facility before they make new system purchase decision and. Precise positioning of AGV by extracting 2D coordinate Abovementioned concept design of AGV may reduce the infrastructure construction cost and be hardly effected by the obstacles. Besides AGV body with excellent performance will reduce the workload of daily maintenance and increases the service life of AGV system. Energies Free Full Text An Energy Consumption Model For Designing An Agv Energy Storage System With A Pemfc Stack Html.

Source: indevagroup.com

Source: indevagroup.com

Automated Guided Vehicles AGV Vision Systems - since 1987. AGVs-based Material Handling Systems MHSs are widely used in several Flexible Manufacturing Systems FMS installations. Automated Guided Vehicles AGV Vision Systems - since 1987. Auto Guided Vehicle AGV Design. Automatic Guided Vehicles Indeva Agv Indeva Group.

Source: semanticscholar.org

Source: semanticscholar.org

Support for integration with most major business and warehouse systems and communication with I O PLC etc. The mini AGV system is based on an autonomous forklift. AGV System Design Modeling and Control. Whatever type of system you are looking for our experienced. Design And Modeling Of Automated Guided Vehicle Systems Using Arduino Semantic Scholar.

Source: researchgate.net

Source: researchgate.net

AGV tunnel tugger under cart etc. This provides users with visual understanding of how their system is designed and how it will operate in their facility before they make new system purchase decision and. The proposed multi-AGV scheduling system was introduced in four aspects system design navigation algorithm path planning algorithm and scheduling algorithm and proved feasible through simulation and experiment. The DeXter System and its accompanying print bed will be mounted to the top of the AGV. Agv Automated Guided Vehicle System Download Scientific Diagram.

Source: hackster.io

Source: hackster.io

Performance of AGV delivery system. The AGV is critical to maximizing DeXters physical capacities in a flexible manufacturing environment. An Automated Guided Vehicle AGV is a set of cooperative driverless vehicle used on manufacturing floor and coordinated by a centralized or distributed computer-based control system. This project aims to collect as much information as possible about AGV systems that currently exist and the subsequent preliminary design of an AGV system for a workshop of TAP Air Portugal Company. Computer Vision Based Navigation System For Industrial Agvs Hackster Io.

Source: mrsdprojects.ri.cmu.edu

Source: mrsdprojects.ri.cmu.edu

To broach these goals the Automated Guided Vehicle AGV was designed to collaborate with another autonomous vehicle the Automated Storage and Retrieval System ASRS. Precise positioning of AGV by extracting 2D coordinate Abovementioned concept design of AGV may reduce the infrastructure construction cost and be hardly effected by the obstacles. Catered to industries whose products can expire the ASRS keeps track of when each. Also these vehicles can come equipped with. System Design 2017 Team F.

Source: researchgate.net

Source: researchgate.net

This document supersedes EN 15251997. The DeXter System and its accompanying print bed will be mounted to the top of the AGV. Amerden AGVS has a proven approach to the design and delivery of an AGV system. Performance of AGV delivery system. Part Fmeca Of Agv System Download Table.

Source: scielo.org.za

Source: scielo.org.za

This provides users with visual understanding of how their system is designed and how it will operate in their facility before they make new system purchase decision and. Precise positioning of AGV by extracting 2D coordinate Abovementioned concept design of AGV may reduce the infrastructure construction cost and be hardly effected by the obstacles. The main objective of this. Lee Procedia Computer Science 00 2018 000â000 Fig. Development Of An Automated Guided Vehicle Controller Using A Model Based Systems Engineering Approach.

Source: researchgate.net

Source: researchgate.net

The command received by the Arduino Mega then will be translated into machine language and then forwarded to the slave. In order to improve the AGVs system efficiency and reliability both Siemens PLC and RFID technologies are applied for the design. The main objective of this. To broach these goals the Automated Guided Vehicle AGV was designed to collaborate with another autonomous vehicle the Automated Storage and Retrieval System ASRS. Agv System Architecture Download Scientific Diagram.

Source: agvnetwork.com

Source: agvnetwork.com

The proposed multi-AGV scheduling system was introduced in four aspects system design navigation algorithm path planning algorithm and scheduling algorithm and proved feasible through simulation and experiment. To broach these goals the Automated Guided Vehicle AGV was designed to collaborate with another autonomous vehicle the Automated Storage and Retrieval System ASRS. AGV System Parameters 200. This document is applicable for mobile platforms including. Agv In Hospitals Autonomous Mobile Robots Disrupting Healthcare Automation.

Source: semanticscholar.org

Source: semanticscholar.org

AGV System Diagram The AGV system to be designed uses Arduino Mega as the prime controller. Lee Procedia Computer Science 00 2018 000â000 Fig. AGVs-based Material Handling Systems MHSs are widely used in several Flexible Manufacturing Systems FMS installations. A fully mobilized multi-functional 3D printer is the next step in implementing industry 40 standards to ensure full automation of a printing operation. Design And Modeling Of Automated Guided Vehicle Systems Using Arduino Semantic Scholar.