Able limit of absorber column. Hello everyone I am currently researching more on the design of a amine stripping column but have met some roadblocks. Amine absorber column design

Amine Absorber Column Design, Material balance for the top part of the column is YA t L V A t X A A LX Y V 52-6 In this equation XA and YA are the mole ratios of A in the liquid and vapor phase respectively at any location in the column including at the two terminals. 2 will be absorbed by the amine solution. If you are designing a new distillation column it is advisable to size for about 60 flooding. While simulating in Promax you can specify maximum limit up to 85.

Flue Gas Purification System Is Regularly The Main Fuel Accessible To Work Power Generators And Compressor Stations In Remote Areas And On Seaward Stages Much From pinterest.com

Flue Gas Purification System Is Regularly The Main Fuel Accessible To Work Power Generators And Compressor Stations In Remote Areas And On Seaward Stages Much From pinterest.com

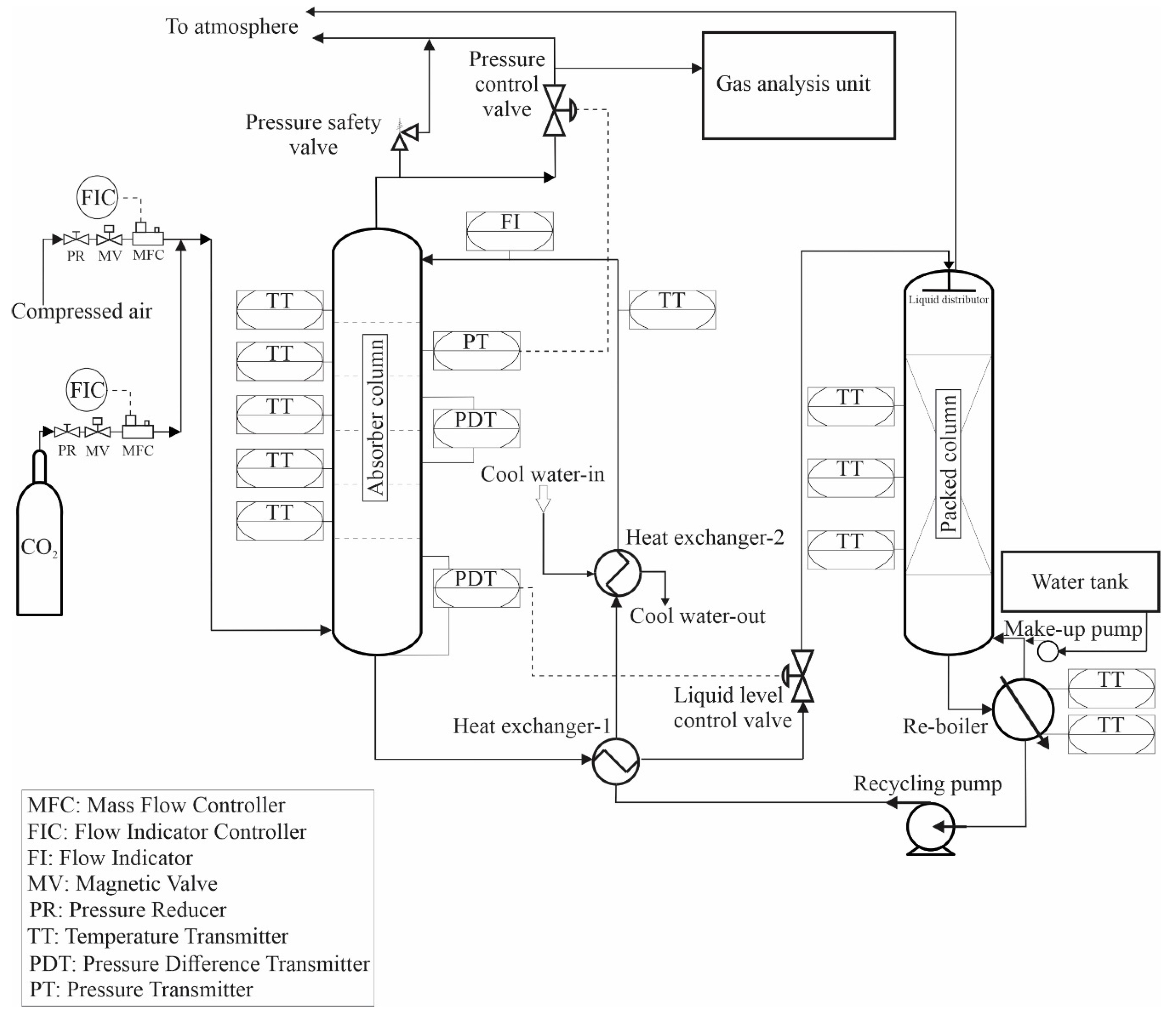

Usually the absorber is a tray column although packed col- umns are also used. The process design of an absorber is based on hydrodynamic and mass transfer considerations. This model does for mass transfer columns what modern heat transfer methodology has done for heat exchanger design. Cooaall m C PPeettrroolleeuum ISSN 1337-7027 Available online at wwwvurupskpc Petroleum Coal 47 2 39-46 2005 AMINE ABSORPTION COLUMN DESIGN USING MASS TRANSFER RATE SIMULATION Kh.

The hydrodynamics in column involves two phase flow namely gas phase to be treated and liquid phase as an absorbent.

Read another article:

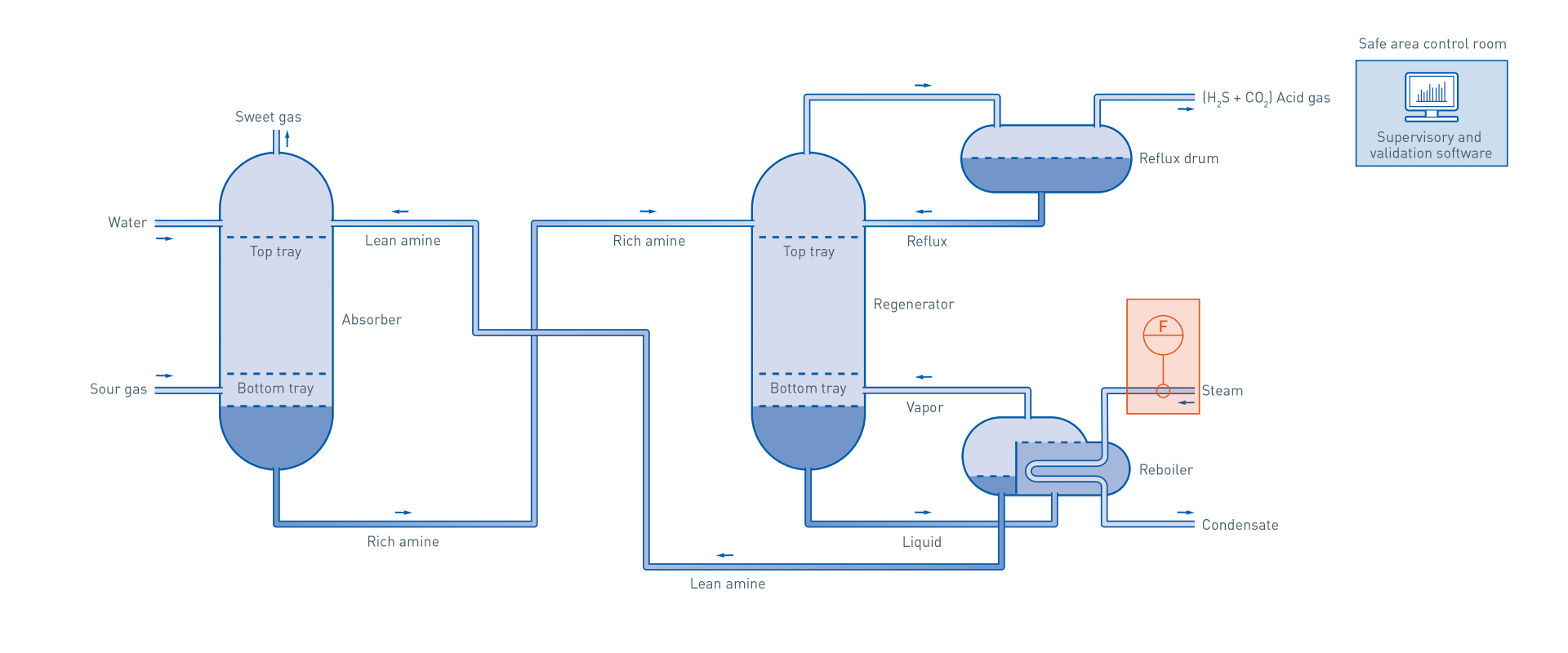

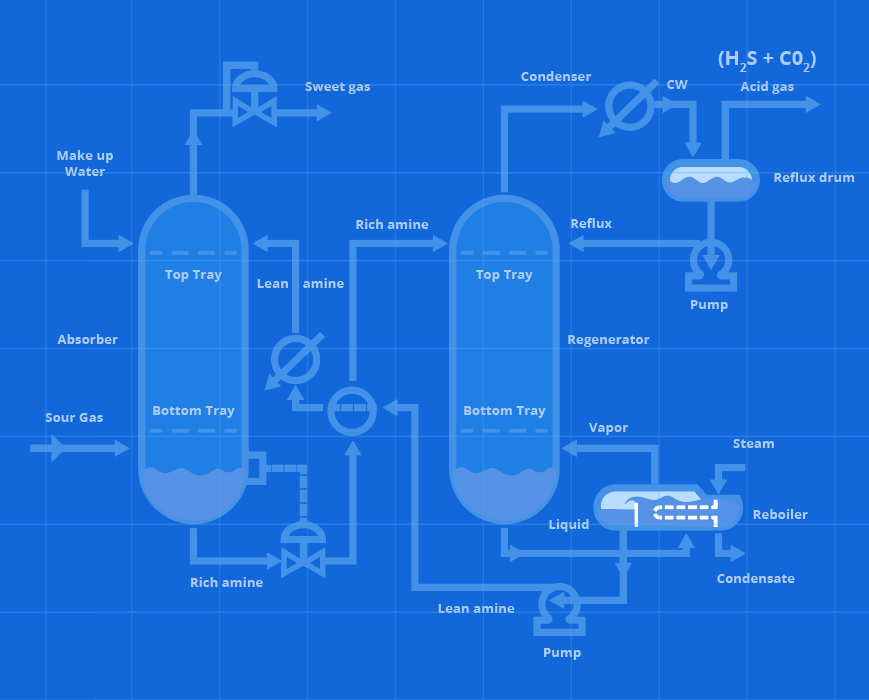

Making Sense of Absorber Temperature Profiles Conventional wisdom seems to be that in amine absorbers the temperature bulge should al-ways be near the bottom of the columnif its not something is wrong and the design may not a good one. This model does for mass transfer columns what modern heat transfer methodology has done for heat exchanger design. Amine plants consist basically of two units Figure 21. While simulating in Promax you can specify maximum limit up to 85. Each of these streams is fed to an amine absorber and the lean amine temperature is varied from 10 to 50C.

Source: nl.krohne.com

Source: nl.krohne.com

Usually the absorber is a tray column although packed col- umns are also used. AMINE ABSORPTION COLUMN DESIGN USING MASS TRANSFER RATE SIMULATION. Using 083 for the study was well within what is expected for this service and provided a representa-tive match to the plant performance. 052307 Amine Best Practices Group Page 4 1. Amine Treatment In The Oil Gas Industry Krohne Netherlands.

Source: researchgate.net

Source: researchgate.net

Amine Absorber T-301 Equipment Specification Name Absorber Column Code T-301 Function To separate CO2 from hydrocarbon Total 2 Operation Data Inside diameter M Outside diameter 5083 M Max flooding 70 Column height 1716 M Column thickness M Stage 26 Column material Stainless Steel SA-167 grade 3 Packing Type Intallox Saddles ceramic 1. Material balance for the top part of the column is YA t L V A t X A A LX Y V 52-6 In this equation XA and YA are the mole ratios of A in the liquid and vapor phase respectively at any location in the column including at the two terminals. Therefore it is necessary to properly allow reasonable first. But this is the maximum recommended for column operation. Diagram Of Inter Stage Cooling On Absorber Column Coupled With Rich Split Download Scientific Diagram.

Source: mdpi.com

Source: mdpi.com

Their design results appear to be unrealistic because it is very unlikely that a single absorber with 913 m diameter can handle the amount of flue. One important design factor of absorber columns is the gas velocity through the absorber packing. Usually the absorber is a tray column although packed col- umns are also used. The lean amine solution accumulates at the bottom of the. Applied Sciences Free Full Text Influence Of Pressure On Gas Liquid Interfacial Area In A Tray Column Html.

Source: researchgate.net

Source: researchgate.net

The mechanical design requirements have an effect on the process operation. The hydrodynamics in column involves two phase flow namely gas phase to be treated and liquid phase as an absorbent. A simplified process flow diagram of amine absorption process is shown in Figure 22. One important design factor of absorber columns is the gas velocity through the absorber packing. Diagram Of Absorber And Stripping Columns Incorporating Split Flow Download Scientific Diagram.

Source: researchgate.net

Source: researchgate.net

Such as amine absorbers is applied. Amine Stripper Column Design - posted in Student. The lean amine solution accumulates at the bottom of the. Global absorption Process by Amines The design of the absorber depends on the gas volume inlet concentration outlet specification pressure temperature liquid circulation rate solubility of the gas in liquid number of trays height contact time diameter of column and the presence of other components in the gas. Details Of The Absorber Configuration 7 Download Scientific Diagram.

Source: researchgate.net

Source: researchgate.net

The design approach of a packed-bed absorber usually involves the determination of geometrical parameters such as tower diameter D and packing height. Each of these streams is fed to an amine absorber and the lean amine temperature is varied from 10 to 50C. This model does for mass transfer columns what modern heat transfer methodology has done for heat exchanger design. The lean amine solution accumulates at the bottom of the. Diagram Of Absorber And Stripping Columns Incorporating Split Flow Download Scientific Diagram.

Source: sciencedirect.com

Source: sciencedirect.com

For a traditional amine-based CO. Material balance for the top part of the column is YA t L V A t X A A LX Y V 52-6 In this equation XA and YA are the mole ratios of A in the liquid and vapor phase respectively at any location in the column including at the two terminals. The flue gas enters the bottom of the absorber and is contacted counter currently with the. The hydrodynamics in column involves two phase flow namely gas phase to be treated and liquid phase as an absorbent. Simulation Model Evaluation Of Desorber Column In Co2 Capture Process By Mea Scrubbing A Rigorous Rate Based Model For Kinetic Model And Mass Transfer Correlations Analysis Sciencedirect.

Source: sciencedirect.com

Source: sciencedirect.com

The process design of an absorber is based on hydrodynamic and mass transfer considerations. Development of a completely new approach to column modeling and analysisthe ProTreat mass transfer rate based tower model. To my best understanding a stripping column is basically the opposite of an absorption column. In either case the objective is to provide intimate contact between the gas and the amine solvent so that the H2S and CO 2 molecules can transfer from the gas phase to the solvent liquid phase. Design Of A Water Wash Column In The Co2 Capture Process Using A Polyamine Based Water Lean Solvent Sciencedirect.

Source: sciencedirect.com

Source: sciencedirect.com

Amine plants consist basically of two units Figure 21. AMINE ABSORPTION COLUMN DESIGN USING MASS TRANSFER RATE SIMULATION. Higher gas velocity leads to higher energy cost due to increased pressure drop but. Two things should be noted. Absorber Tower An Overview Sciencedirect Topics.

Source: researchgate.net

Source: researchgate.net

Since condensing a non-aqueous phase is of concern the hydrocarbon dew point is what is most important and is shown in Table 1. As it is heated steam from heating the amine rises as rich amine ows downward through the still column stripping out the CO 2 and H 2 S. Two things should be noted. Rich amine solution is further treated in a stripper or still. Flow Scheme Of Absorption Column With Intercooling Download Scientific Diagram.

Source: researchgate.net

Source: researchgate.net

Their design results appear to be unrealistic because it is very unlikely that a single absorber with 913 m diameter can handle the amount of flue. Such as amine absorbers is applied. The Inlet Knockout Drum functions to catch entrained hydrocarbon liquids and occasional slugs. Treated gas lean gas or sweet gas leaves the top of the column and the amine solution loaded with acid gas rich solution leaves the bottom of the column. Flue Gas From A Coal Fired Power Plant Is Piped Into An Absorber Column Download Scientific Diagram.

Source: semanticscholar.org

Source: semanticscholar.org

Binesh Research Institute of. Making Sense of Absorber Temperature Profiles Conventional wisdom seems to be that in amine absorbers the temperature bulge should al-ways be near the bottom of the columnif its not something is wrong and the design may not a good one. Table 2 shows the tray evaluation results. The flue gas enters the bottom of the absorber and is contacted counter currently with the. Pdf Design Of A Packed Bed Absorption Column Considering Four Packing Types And Applying Matlab Semantic Scholar.

The column hydrodynamics through mass transfer coefficients kLa and kGa has significant influence on process design based on mass transfer. Absorber Objective Acid gas removal from feed Characteristics - Fractionation column equipped with trays generally around 20 or packing beds generally 2 or 3 beds. Amine Absorber T-301 Equipment Specification Name Absorber Column Code T-301 Function To separate CO2 from hydrocarbon Total 2 Operation Data Inside diameter M Outside diameter 5083 M Max flooding 70 Column height 1716 M Column thickness M Stage 26 Column material Stainless Steel SA-167 grade 3 Packing Type Intallox Saddles ceramic 1. Several mechanical design considerations must be taken into account in proper absorber vessel design to ensure that this will occur. 2.

Source: carverpump.com

Source: carverpump.com

Amine Absorber T-301 Equipment Specification Name Absorber Column Code T-301 Function To separate CO2 from hydrocarbon Total 2 Operation Data Inside diameter M Outside diameter 5083 M Max flooding 70 Column height 1716 M Column thickness M Stage 26 Column material Stainless Steel SA-167 grade 3 Packing Type Intallox Saddles ceramic 1. The rich amine solution is then boiled in a reboiler allowing the CO2 and H2S to be released as gaseous vapour in the stripper column Figure 1. Higher gas velocity leads to higher energy cost due to increased pressure drop but. It models towers in full detail as real physical equipment. Amine Scrubbing System Overview.

Source: semanticscholar.org

Source: semanticscholar.org

Able limit of absorber column. Using 083 for the study was well within what is expected for this service and provided a representa-tive match to the plant performance. Material balance for the top part of the column is YA t L V A t X A A LX Y V 52-6 In this equation XA and YA are the mole ratios of A in the liquid and vapor phase respectively at any location in the column including at the two terminals. Such as amine absorbers is applied. Pdf Design Of A Packed Bed Absorption Column Considering Four Packing Types And Applying Matlab Semantic Scholar.