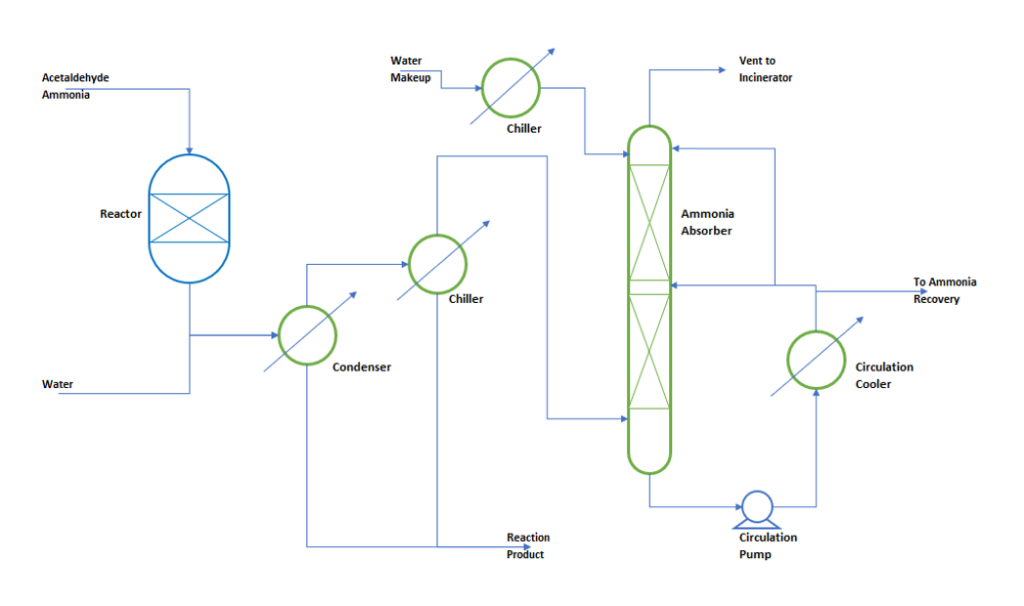

The design consists in determining all the construction parameters for the air cooled. From generator pure x gen from absorber rich x abs solution flows where m abs m gen m ref logically. Ammonia absorber design

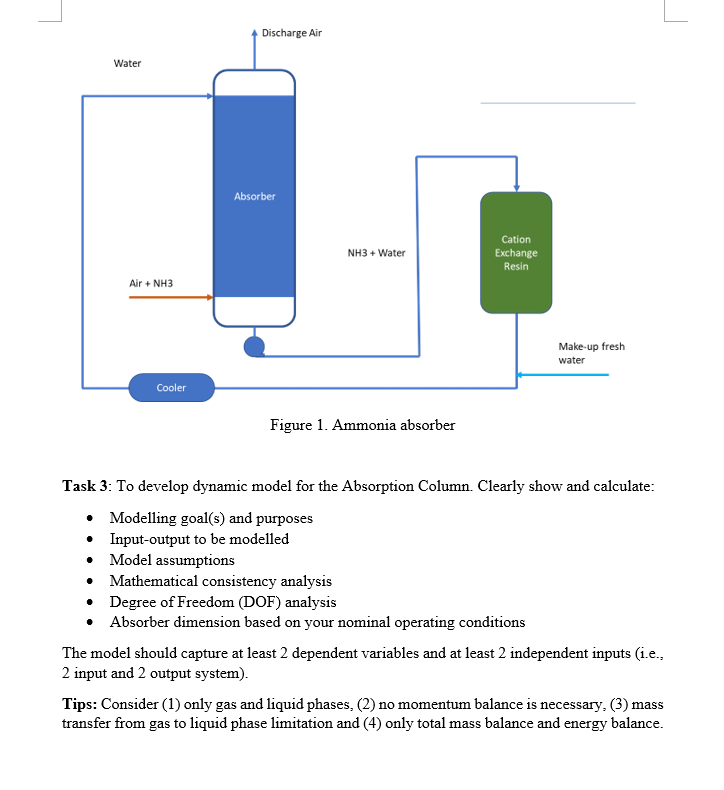

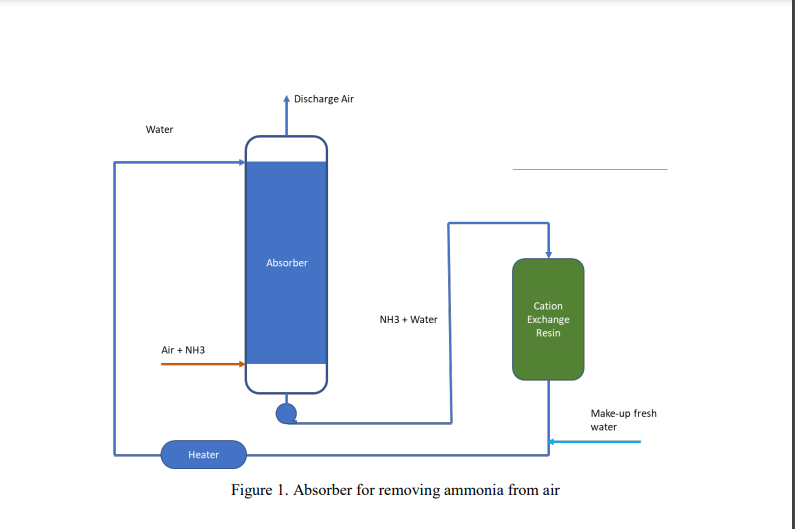

Ammonia Absorber Design, The required amount of ammonia to be absorbed into the weak solution can be as low as 3. Absorber spray absorber and packed column absorber are the five configurations that are discussed in relation to the combined cycle. This is why the solution must be circulated. Hi Im designing an absorber to absorb ammonia out of a relief valve using water.

Thermodynamic Analysis And Experimental Validation Of Multi Composition Ammonia Liquor Absorption Engine Cycle For Power Generation Satpute 2020 International Journal Of Energy Research Wiley Online Library From onlinelibrary.wiley.com

Thermodynamic Analysis And Experimental Validation Of Multi Composition Ammonia Liquor Absorption Engine Cycle For Power Generation Satpute 2020 International Journal Of Energy Research Wiley Online Library From onlinelibrary.wiley.com

Need help to design an ammonia absorber. The scrubbing solution is then a very small say 1 m3h trickle of water. The region where the temperature variation occurred was larger at the higher gas flow rate and in the solution of higher concentration. The absorbent will be brine solution.

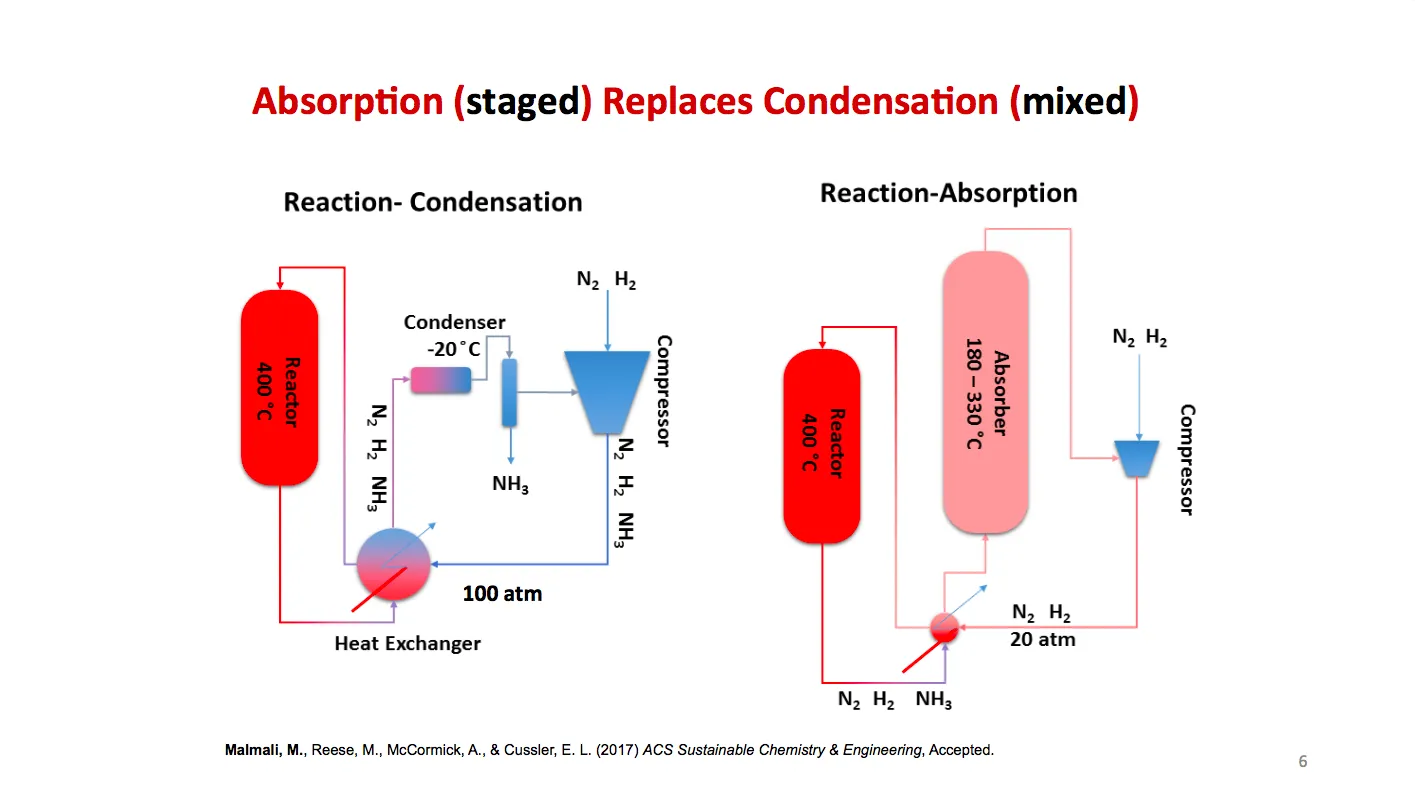

The energy source is usually hydrocarbons thus providing hydrogen as well but may also be coal or electricity.

Read another article:

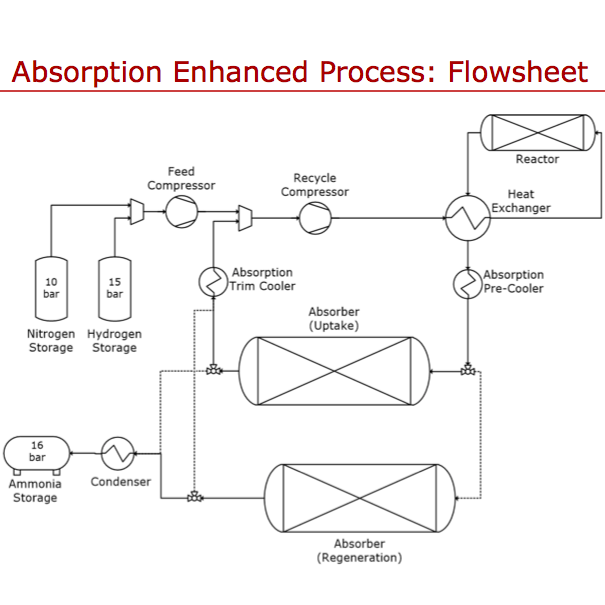

The design consists in determining all the construction parameters for the air cooled ammonia absorption unit starting with the operating conditions defined by a. Equipments used from aspen Hysys in the simulation of ammonia plant design are shown in Table 1. The design consists in determining all the construction parameters for the air cooled. Ammonia absorption plants are typically driven by hot water or steam but with an adapted design it is possible to get the required heat directly from any hot gases or liquids. Absorber to the bottom of the absorber where the gas flowed in.

Source: ammoniaenergy.org

Source: ammoniaenergy.org

From generator pure x gen from absorber rich x abs solution flows where m abs m gen m ref logically. This component also called generator does the opposite of the absorber. The desorber is heated in order to boil out the solution and release the ammonia vapor. Im currently designing an ammonia absorption tower. Improvement Of Haber Bosch Adsorption Vs Absorption Ammonia Energy Association.

Source: chemengghelp.com

Source: chemengghelp.com

Conceptual design of ammonia-based energy storage system. The absorber is a fixed bed of magnesium chloride supported on silica. It means that the ammonia gas is not absorbed well on the condition of high gas flow rate and high concentration solution. Steam reforming of light hydrocarbons is the most efficient route with about 77 of world ammonia capacity being based on natural gas. Process Design Calculations For Ammonia Absorber Chemengghelp.

Source: ammoniaenergy.org

Source: ammoniaenergy.org

Ammonia Absorber - posted in Student. How the design procedure differ if the stream is pure ammonia. This unit loses ammonia constantly so this is recovered. Aqueous Ammonia storage usually has a very small scrubber attached made from a 300 mm NB pipe with about 2 m of 15 mm Pall Rings. Improvement Of Haber Bosch Adsorption Vs Absorption Ammonia Energy Association.

The design consists in determining all the construction parameters for the air cooled. This is why the solution must be circulated. For our absorber we will design for 42mm water in packing. 02 April 2020 These design guideline are believed to be as accurate as possible but are very general and not for specific design cases. Solved Project Statement 5 Modelling And Control Of Nh3 Air Chegg Com.

Source: onlinelibrary.wiley.com

Source: onlinelibrary.wiley.com

And results of the basic and detailed engineering for a descending film ammonia absorber using air cooled finned tubes which is part of an advanced absorption cooling system solar generator absorber heat exchange cycle. Steam reforming of light hydrocarbons is the most efficient route with about 77 of world ammonia capacity being based on natural gas. From generator pure x gen from absorber rich x abs solution flows where m abs m gen m ref logically. Google Scholar Green Version. Thermodynamic Analysis And Experimental Validation Of Multi Composition Ammonia Liquor Absorption Engine Cycle For Power Generation Satpute 2020 International Journal Of Energy Research Wiley Online Library.

It means that the ammonia gas is not absorbed well on the condition of high gas flow rate and high concentration solution. The desorber is heated in order to boil out the solution and release the ammonia vapor. The absorber is a fixed bed of magnesium chloride supported on silica. Absorber design and performance. 2.

Source: chegg.com

Source: chegg.com

Hi Im designing an absorber to absorb ammonia out of a relief valve using water. This paper presents the design criteria methodology. The desorber is heated in order to boil out the solution and release the ammonia vapor. Of Process Equipment Design Ammonia Plant Selection Sizing and Troubleshooting ENGINEERING DESIGN GUIDELINES Page 7 of 181 Rev. Project Statement 5 Modelling And Control Of Nh4 Air Chegg Com.

Source: researchgate.net

Source: researchgate.net

Ammonia absorption plants are typically driven by hot water or steam but with an adapted design it is possible to get the required heat directly from any hot gases or liquids. The design consists in determining all the construction parameters for the air cooled. This paper presents the design criteria methodology. However the resistance to mass transfer inside the bubbles was neglected in the model. Scheme 1 Ammonia Absorption Precooling Cycle Download Scientific Diagram.

Source: researchgate.net

Source: researchgate.net

Ammonia is produced basically from water air and energy. Hi Im designing an absorber to absorb ammonia out of a relief valve using water. From generator pure x gen from absorber rich x abs solution flows where m abs m gen m ref logically. Ammonia absorption plants are typically driven by hot water or steam but with an adapted design it is possible to get the required heat directly from any hot gases or liquids. Pdf Optimization Of Ammonia Absorption Using Acid Spray Wet Scrubbers.

Source: chemistry.stackexchange.com

Source: chemistry.stackexchange.com

DESIGN OF ABSORBER CHAPTER No8 DESIGN OF ABSORBER 81 ABSORPTION The removal of one or more component from the mixture of gases by using a suitable solvent is second major operation of Chemical Engineering that based on mass transfer. Absorber spray absorber and packed column absorber are the five configurations that are discussed in relation to the combined cycle. The absorber is a fixed bed of magnesium chloride supported on silica. Thus for 42mm of water m of packing height K 4 14 Fp 223 μ L viscosity of water at 45 0C 63 Cp G K4 v l - v 131 Fp μ L l 12 G 606 Kg m2sec. Improving Efficiency Of Absorption Refrigerator Ammonia Hydrogen Chemistry Stack Exchange.

Source: chemengghelp.com

Source: chemengghelp.com

The region where the temperature variation occurred was larger at the higher gas flow rate and in the solution of higher concentration. This paper presents the design criteria methodology. Ammonia air scrubbers incorporate a variety of gas-liquid contacting techniques including packed beds spray chambers and water jets. Ammonia 21 Experimental review Absorptio In case of falling film its seen that vapour absorption is increased by film inverting design and by establishing magnetic field in same direction as falling film 177. Process Design Calculations For Ammonia Absorber Chemengghelp.

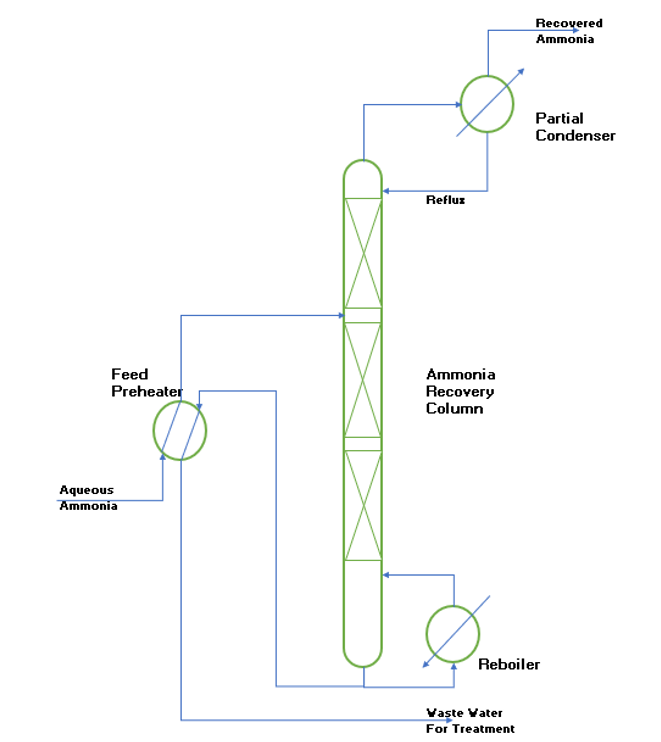

Of Process Equipment Design Ammonia Plant Selection Sizing and Troubleshooting ENGINEERING DESIGN GUIDELINES Page 7 of 181 Rev. For our absorber we will design for 42mm water in packing. Google Scholar Green Version. The design consists in determining all the construction parameters for the air cooled ammonia absorption unit starting with the operating conditions defined by a. Ammonia Absorption Refrigeration System 1 Distillation Tower Download Scientific Diagram.

Source: arizonaenergy.org

Source: arizonaenergy.org

Herbine and Pérez- Blanco 10 developed a model for the absorption process in an ammoniawater bubble absorber with a vertical tube which yielded temperature and concentration profiles along the absorber. Ammonia absorption plants are typically driven by hot water or steam but with an adapted design it is possible to get the required heat directly from any hot gases or liquids. The scrubbing solution is then a very small say 1 m3h trickle of water. This component also called generator does the opposite of the absorber. Small Ammonia Refrigerator.

Source: chemengghelp.com

Source: chemengghelp.com

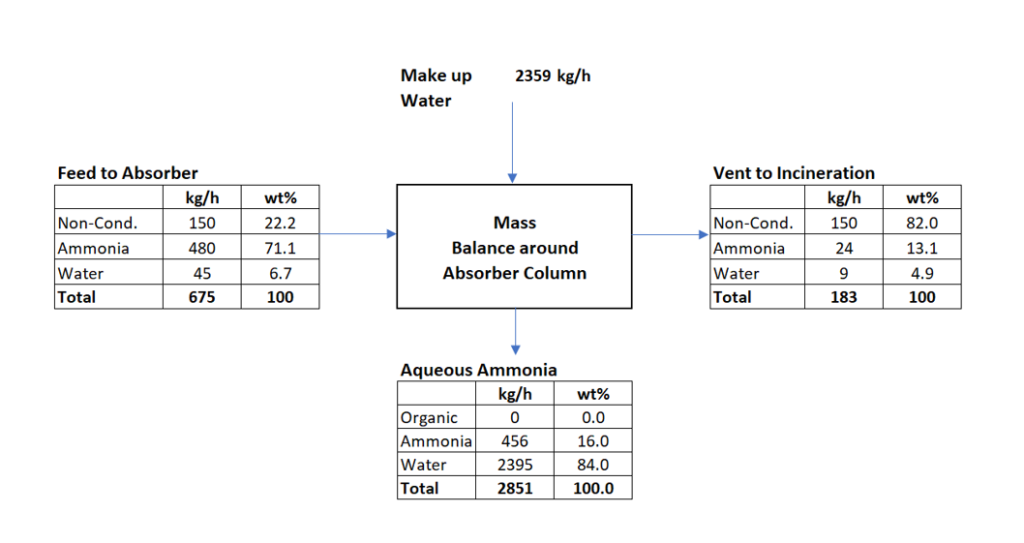

The required amount of ammonia to be absorbed into the weak solution can be as low as 3. It means that the ammonia gas is not absorbed well on the condition of high gas flow rate and high concentration solution. Absorber design and performance. Absorber to the bottom of the absorber where the gas flowed in. Ammonia Recovery Process Design Calculation Chemengghelp.

Source: researchgate.net

Source: researchgate.net

DESIGN OF ABSORBER CHAPTER No8 DESIGN OF ABSORBER 81 ABSORPTION The removal of one or more component from the mixture of gases by using a suitable solvent is second major operation of Chemical Engineering that based on mass transfer. Thus for 42mm of water m of packing height K 4 14 Fp 223 μ L viscosity of water at 45 0C 63 Cp G K4 v l - v 131 Fp μ L l 12 G 606 Kg m2sec. Hi Im designing an absorber to absorb ammonia out of a relief valve using water. Im currently designing an ammonia absorption tower. Absorbent Enhanced Ammonia Synthesis Process Flow Diagram Download Scientific Diagram.