DNVGL Design Factor Data Module. TABLE 841114B DESIGN FACTORS FOR STEEL PIPE CONSTRUCTION. Asme b31 8 design factor

Asme B31 8 Design Factor, ASME B318 INTERPRETATIONS VOLUME 16 Interpretation. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. For onshore pipelines and offshore platform piping the allowable pressure is the maximum allowable design pressure for the pipeline location class and facility type. ASME has been defining piping safety since 1922.

Design Engineering Of Crude Oil And Natural Gas Pipelines From piping-world.com

Design Engineering Of Crude Oil And Natural Gas Pipelines From piping-world.com

See table 841116A at ASME B318 Code. ASME B313 Process Piping Design Factor Data Module. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. 8422 Design of Plastic Piping General Provisions Date Issued.

TABLE 841114B DESIGN FACTORS FOR STEEL PIPE CONSTRUCTION.

Read another article:

B318 makes no distinction between socket welds with undercut and socket welds without undercut. Smart pig or ILI will be used to inspect the pipeline every 5 years. F design factor. - Piping Design Factor. Is that b c shall not exceed 54 of SMYS 75 of 72 for design factor 072 locations.

Source: communities.bentley.com

Source: communities.bentley.com

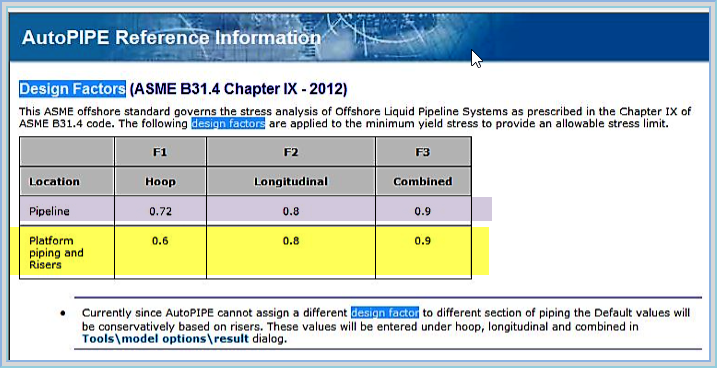

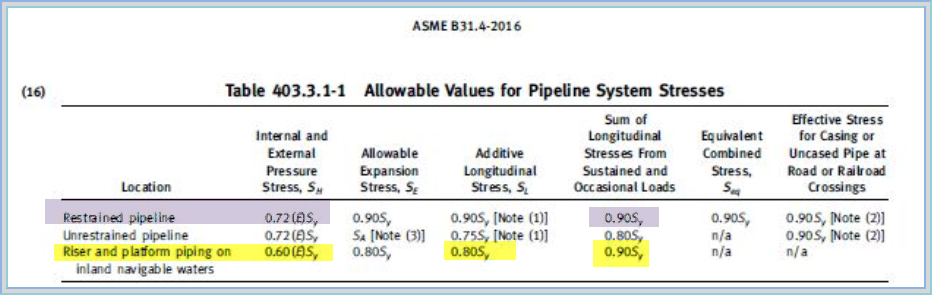

Material Elastic Modulus And Poisson Ratio Data Module. But ASME B314 deals with pipelines transporting liquids and slurries whereas ASME B318 deals with gas transmission and distribution. For on-shore piping B314 that field for F indicates the amount the pipeline may be considered under complete axial restraint. B314 and B314 Ch IX are treated as two different Piping Codes in CAESAR II. 01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities.

Source: mechanicalengineerblog.com

Source: mechanicalengineerblog.com

Modifications to the flexibility factor and Stress Intensification Factor SIF using B318 Modifications to the flexibility factor and SIF of bends resulting from flange d ends are permitted by the code. See table 841116A at ASME B318 Code. Kindly note that the exceptions to the design factors are shown in table 84116-2 of ASME B318. ASME B318-2007 Revision of ASME B318-2003 Gas Transmission and Distribution Piping Systems. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

Source: semanticscholar.org

Source: semanticscholar.org

See Table 841114B of ASME B318 for exceptions to the design factor. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. For onshore pipelines and offshore platform piping the allowable pressure is the maximum allowable design pressure for the pipeline location class and facility type. Factor Design Pressure This document uses the Barlows equation to find the design pretssure for a steel pipe. A Comparison Of Inherent Risk Levels In Asme B31 8 And Uk Gas Pipeline Design Codes Semantic Scholar.

ASME B318 INTERPRETATIONS VOLUME 16 Interpretation. This is covered in ASME B314 Article 402 and of ASME B318 Article 833. 08 072 06 05 04. An interpretation of this requirement. Asme B31 8 Riser Calc Pdf Pipe Fluid Conveyance Plumbing.

Source: mechanicalengineerblog.com

Source: mechanicalengineerblog.com

This is covered in ASME B314 Article 402 and of ASME B318 Article 833. 0246 inches PASS Design Pressure 1250 2 St FET ASME B 318 NA inch 42000 inch inch Sch. These exceptions include compressor station piping pipelines on bridges pipeline crossing roads etc. But ASME B314 deals with pipelines transporting liquids and slurries whereas ASME B318 deals with gas transmission and distribution. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

Source: mechanicalengineerblog.com

Source: mechanicalengineerblog.com

ASME B318 2010 table 84116-2 design factor for pipe Class 1 location. Is that b c shall not exceed 54 of SMYS 75 of 72 for design factor 072 locations. For onshore pipelines and offshore platform piping the allowable pressure is the maximum allowable design pressure for the pipeline location class and facility type. TABLE 841114B DESIGN FACTORS FOR STEEL PIPE CONSTRUCTION. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

Source: communities.bentley.com

Source: communities.bentley.com

The maximum value is 08 not 10 and the lowest value is 04. Not exceed 75 of the allowable stress in the hot condition. - Piping Design Factor. Material Elastic Modulus And Poisson Ratio Data Module. 01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities.

Source: communities.bentley.com

Source: communities.bentley.com

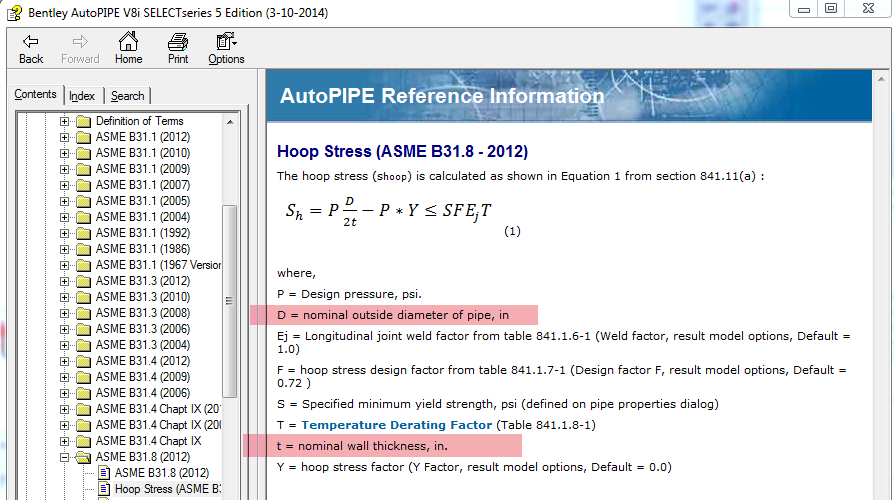

ASME B314 vs ASME B318. March 22 2011 File. A Hoop Stress page 104 Sh F1ST F1 hoop stress design factor from Table A84222-1 S specified minimum yield strength psi MPa Sh hoop stress psi MPa. Modifications to the flexibility factor and Stress Intensification Factor SIF using B318 Modifications to the flexibility factor and SIF of bends resulting from flange d ends are permitted by the code. 04 Using Asme B31 8 2012 2016 How Is The Hoop Stress Being Calculated In Autopipe Autopipe Wiki Autopipe Bentley Communities.

Source: mechanicalengineerblog.com

Source: mechanicalengineerblog.com

ASME B318 Gas Pipeline Design Pressure Calculator Module Calculate ASME B318 gas pipeline maximum allowable design pressure from allowable stress and pressure design wall thickness. The wall thickness initially derived from hoop stress considerations based on design factors should be such that the longitudinal shear and equivalent stresses in the pipe wall under functional and environmental loads do not exceed certain values. This equation is used in ASME B318 - Gas Transmission and Distribtuion Piping Systems. Using CAESAR II and pipe stress calculations as per API ASME B313 B311 B318 B314 B319 CSA Z662. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

This article is about DOWNLOAD ASME B318 GAS TRANSMISSION AND DISTRIBUTION PIPING SYSTEMS Piping System Components and Fabrication Details ASME Standards. A Hoop Stress page 104 Sh F1ST F1 hoop stress design factor from Table A84222-1 S specified minimum yield strength psi MPa Sh hoop stress psi MPa. Factor Design Pressure This document uses the Barlows equation to find the design pretssure for a steel pipe. The maximum value is 08 not 10 and the lowest value is 04. B31 8 Steel Piping Design Formula Pdf Pipe Fluid Conveyance Corrosion.

Source: communities.bentley.com

Source: communities.bentley.com

ASME B318 INTERPRETATIONS VOLUME 16 Interpretation. B318 makes no distinction between socket welds with undercut and socket welds without undercut. See table 841116A at ASME B318 Code. Is that b c shall not exceed 54 of SMYS 75 of 72 for design factor 072 locations. 04 Using Asme B31 8 2012 2016 How Is The Hoop Stress Being Calculated In Autopipe Autopipe Wiki Autopipe Bentley Communities.

Modifications to the flexibility factor and Stress Intensification Factor SIF using B318 Modifications to the flexibility factor and SIF of bends resulting from flange d ends are permitted by the code. Please note the design temperature is 250 F 120 C so this is acceptable for using ASME B314 code. Class 1 Division 2 - A Location Class 1 where the design factor of the pipe is equal to or less than 072 but equal to or less than 080 and which has been hydrostatically tested to 11 times the maximum operating pressure. Reinforced thermoplastic pipe RTP as described in for example ISO TS 18226. Fianagusta Blogspot Com.

So both the codes ASME B314 and ASME B318 are pipeline design codes that cover the design fabrication installation inspection and testing of pipeline facilities. For onshore pipelines and offshore platform piping the allowable pressure is the maximum allowable design pressure for the pipeline location class and facility type. We serve all types of industries across Canada globally. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. Asme B31 8 Pdf Pipe Fluid Conveyance Gas Technologies.

Source: semanticscholar.org

Source: semanticscholar.org

ASME B318 covers gas transmission and distribution piping systems including gas pipelines gas compressor stations gas metering and regulation stations gas mains and service lines up to the outlet of the customers meter set assembly. B314 and B314 Ch IX are treated as two different Piping Codes in CAESAR II. Factor Design Pressure This document uses the Barlows equation to find the design pretssure for a steel pipe. Paragraph 8334 of ANSIIASME 8318 states that The sum of 8334b and c shall. Table 2 From A Comparison Of Inherent Risk Levels In Asme B31 8 And Uk Gas Pipeline Design Codes Semantic Scholar.

Source: communities.bentley.com

Source: communities.bentley.com

E T O F D inch P design Psig. If you use the Buried Pipe Modeler CAESAR II fills this in for you. ASME B318 INTERPRETATIONS VOLUME 16 Interpretation. Not exceed 75 of the allowable stress in the hot condition. 01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities.