The following inputs are required for pressure vessel design. Geometrical specification of the pressure vessel Thickness calculation from ASME codes Finite element verification of the code Design optimization using finite element analysis Results representation 33 Design Requirements Inner diameter of the pressure vessel d3500mm Design Pressure. Asme standard for pressure vessel design

Asme Standard For Pressure Vessel Design, ASME SECTION VIII For Pressure Vessels. The following pressure vessel design guide and resources will help you efficiently optimize your design before moving on to the actual manufacturing and. It has following Divisions. Pressure Vessels and project technical requirements.

Asme Boiler And Pressure Vessel Code The American Society Of From pdfprof.com

Asme Boiler And Pressure Vessel Code The American Society Of From pdfprof.com

Division 2 alternative rules. Because of that the design and Certification of pressure vessels is governed by design codes such as The ASME Boiler and Pressure Vessel Code in North America the Pressure Equipment Directive of the EU PED Japanese Industrial Standard JIS CSA B51 in Canada AS1210 in Australia and other international standards like Lloyds Germanischer Lloyd Det Norske. 6 Hoon-Seok Byun The present and the futureoftheKoreaelectricpowerindustry code ASME PVP 2008. LANL Engineering Standards Manual STD-342-100 Chapter 17-Pressure Safety Section REF References Rev.

Pressure Vessels and project technical requirements.

Read another article:

Roarks Formulas for Stress and Strain 7th edition Table 92 Case 1 Pressure Vessel Design Manual 3rd Edition ASME B311-2006. In 1916 shortly after the first publication of the Rules for the Construction of Stationary Boilers and. The worlds most recognised design code for pressure vessels comprises two Divisions. Normally the ASME Sec VIII code governs the design of pressure vessels. The design materials fabrication inspection testing and documentation of pressure vessels should be in full accordance with the ASME Boiler and Pressure Vessel Code Section VIII Division 1 or Division 2.

Source: researchgate.net

Source: researchgate.net

The following pressure vessel design guide and resources will help you efficiently optimize your design before moving on to the actual manufacturing and. ASME B313 Process Piping Guide. A ruptured pressure vessel can cause serious irreversible harm to mankind and properties. This spreadsheet calculates the a variety of resultant engineering requirments per. Manual Calculation For Designing Pressure Using Asme Code Download Scientific Diagram.

Source: studylib.net

Source: studylib.net

All Addenda issued through the date of the Agreement Contract or. The ASME Code Section 8 is the construction code for pressure vessel and covers design manufacturing and pressure vessel inspection and testing in the manufacturing shop. For fixed pressure vessels. While chemical engineers will generally not carry out the immediate design they will need to communicate specifications based on their understanding of process conditions to the vessel design engineers. Review On Stresses In Cylindrical Pressure Vessel Sumit V Dubal.

Source: boardmaninc.com

Source: boardmaninc.com

H and Bednar H. The worlds most recognised design code for pressure vessels comprises two Divisions. It has following Divisions. H and Bednar H. Volume Xliii I Asme Sec I Sec Viii Fundamentals Boardman Llc.

Source: docplayer.net

Source: docplayer.net

A ruptured pressure vessel can cause serious irreversible harm to mankind and properties. The following inputs are required for pressure vessel design. The design of vertical pressure vessel is carried out using the American Society of Mechanical Engineers ASME Codes. ASME SECTION VIII For Pressure Vessels. Design Inspection Testing And Repair Of Asme Coded Pressure Systems And Safety Relief Valves Pdf Free Download.

Source: pveng.com

Source: pveng.com

A leading standard for pressure equipment and components worldwide the ASME Boiler and Pressure Vessel Code ASME Code provides requirements for manufacturer certification and quality assurance. The ASME Code Section 8 is the construction code for pressure vessel and covers design manufacturing and pressure vessel inspection and testing in the manufacturing shop. In most countries pressure vessels must be manufactured to a certain code and in the United States that code is the Boiler and Pressure Vessel Code BPVC from the American Society of Mechanical Engineers ASME. The design materials fabrication inspection testing and documentation of pressure vessels should be in full accordance with the ASME Boiler and Pressure Vessel Code Section VIII Division 1 or Division 2. Audit Vessel Pressure Vessel Engineering.

Source: globalspec.com

Source: globalspec.com

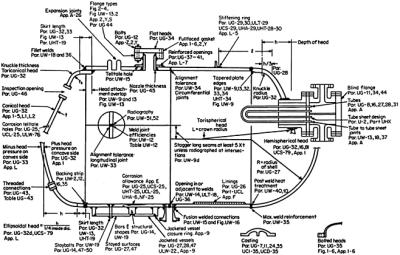

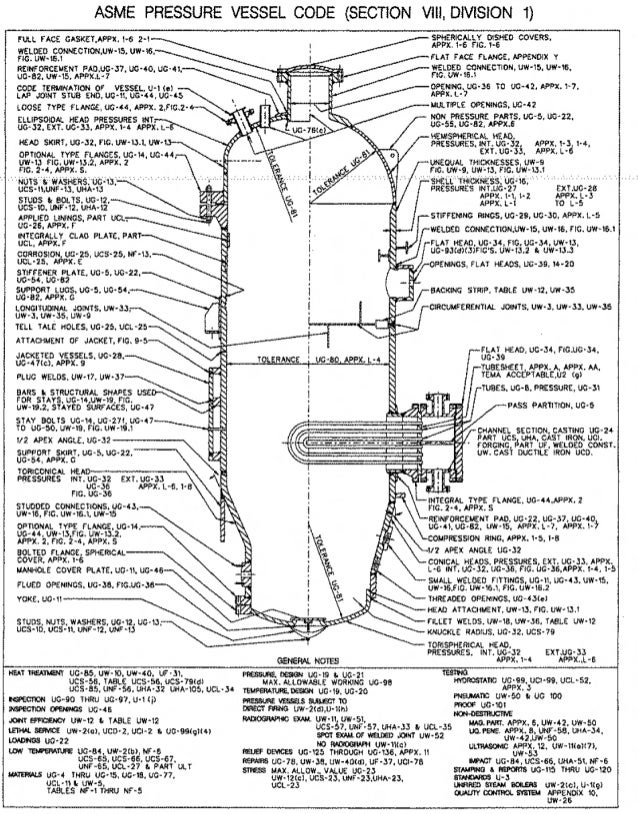

0 09172014 REF-3 ASME B313 Process Piping Guide 1 of 171. These rules may also apply to human occupancy pressure vessels typically in the diving industry. Division 2 alternative rules. 0 09172014 REF-3 ASME B313 Process Piping Guide 1 of 171. Html Head Chapter 2 Descriptive Guide To The Asme Code Section Viii Division 1 Pressure Vessels Engineering360.

Source: pt.slideshare.net

Source: pt.slideshare.net

ASME SECTION VIII For Pressure Vessels. The design materials fabrication inspection testing and documentation of pressure vessels should be in full accordance with the ASME Boiler and Pressure Vessel Code Section VIII Division 1 or Division 2. Pressure Vessel Design Handbook Second Edition Pressure Vessel Design Handbook. Geometrical specification of the pressure vessel Thickness calculation from ASME codes Finite element verification of the code Design optimization using finite element analysis Results representation 33 Design Requirements Inner diameter of the pressure vessel d3500mm Design Pressure. Guidebook For The Design Of Asme Section Viii Pressure Vessel.

Source: pdf4pro.com

Source: pdf4pro.com

ASME Code Pressure Vessel Design Capabilities of Rexarc All our pressure vessel designs adhere to the specifications established in the ASME Boiler and Pressure Vessel Code BPVC Section VIII. Roarks Formulas for Stress and Strain 7th edition Table 92 Case 1 Pressure Vessel Design Manual 3rd Edition ASME B311-2006. The ASME Code Section 8 is the construction code for pressure vessel and covers design manufacturing and pressure vessel inspection and testing in the manufacturing shop. About the ASME Boiler and Pressure Vessel Certification Program. Pressure Vessels Part I Pressure Vessel Design Shell Pressure Vessels Part I Pressure Vessel Design Shell Pdf Pdf4pro.

Source: pveng.com

Source: pveng.com

In most countries pressure vessels must be manufactured to a certain code and in the United States that code is the Boiler and Pressure Vessel Code BPVC from the American Society of Mechanical Engineers ASME. Standards on pressure vessel and apparatus design and strength calculation ASME PVP 2009. ASMEs Boiler and Pressure Vessel Code BPVC 2013 Pressure Vessels Division 2 requirements on materials design and nondestructive examination are more rigorous than in Division 1. The document is written and maintained by volunteers chosen for their technical expertise. Water Softener Vessel Pressure Vessel Engineering.

Source: chegg.com

Source: chegg.com

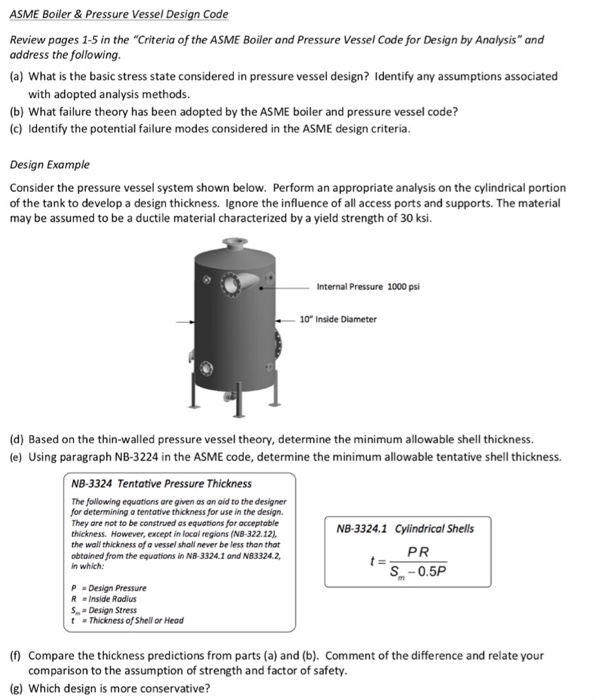

Pressure Vessel Design Handbook Second Edition Pressure Vessel Design Handbook. ASME codes are used for pressurized equipment vessels piping and fittings in North America and many other countries. H and Bednar H. About the ASME Boiler and Pressure Vessel Certification Program. Solved Asme Boiler Pressure Vessel Design Code Review Chegg Com.

Source: youtube.com

Source: youtube.com

The worlds most recognised design code for pressure vessels comprises two Divisions. Division 2 alternative rules. The design materials fabrication inspection testing and documentation of pressure vessels should be in full accordance with the ASME Boiler and Pressure Vessel Code Section VIII Division 1 or Division 2. These rules may also apply to human occupancy pressure vessels typically in the diving industry. Asme Code Pressure Vessel Design Youtube.

Source: pdfprof.com

Source: pdfprof.com

Most commonly used ASME codes are. For all pressure vessels including those covered by Division 2 and. In 1916 shortly after the first publication of the Rules for the Construction of Stationary Boilers and. 6 Hoon-Seok Byun The present and the futureoftheKoreaelectricpowerindustry code ASME PVP 2008. Asme Boiler And Pressure Vessel Code The American Society Of.

Source: onlinelibrary.wiley.com

Source: onlinelibrary.wiley.com

The worlds most recognised design code for pressure vessels comprises two Divisions. LANL Engineering Standards Manual STD-342-100 Chapter 17-Pressure Safety Section REF References Rev. The worlds most recognised design code for pressure vessels comprises two Divisions. All Addenda issued through the date of the Agreement Contract or. Sample Of Pressure Vessel Design Data Sheets Structural Analysis And Design Of Process Equipment Wiley Online Library.

Source: semanticscholar.org

Source: semanticscholar.org

Most commonly used ASME codes are. The ASME VIII code provides design manufacture and inspection rules for all pressure vessels and. A ruptured pressure vessel can cause serious irreversible harm to mankind and properties. Normally the ASME Sec VIII code governs the design of pressure vessels. Pdf Comparison Of Pressure Vessel Codes Asme Section Viii And En13445 Semantic Scholar.

Source: grabcad.com

Source: grabcad.com

For all pressure vessels including those covered by Division 2 and. ASME B313 Process Piping Guide. Division 1 mandatory rules. However higher design stress intensify values are permitted. Pressure Vessel Asme Standard 8 3d Cad Model Library Grabcad.