This method would be used by City and County Roadway Departments State Departments of Transportation. Good indication of a mixtures. Asphalt institute design procedure

Asphalt Institute Design Procedure, Asphalt Paving Design Guide prepared for the Asphalt Pavement Association of Oregon 5240 Gaffin Road SE Salem OR 97301 by RG. The purpose of this Guidance Note is to ensure that a. Determine the proportion of each aggregate size required to produce the design grading. MODEL PROCEDURE FOR PERFORMANCE BASED MIX DESIGN AND ACCEPTANCE OF HOT MIX ASPHALT 1.

Component Analysis Asphalt Institute Pavement Interactive From pavementinteractive.org

Component Analysis Asphalt Institute Pavement Interactive From pavementinteractive.org

The Marshall mix design method can use any suitable method for estimating optimum asphalt content and usually relies on local procedures or experience. This is because the Asphalt Institute design method requires complex calculations of the horizontal strains induced in the pavement system under load. Asphalt Institute Foundation About Us Through education engineering technical development environmental stewardship and marketing leadership the Asphalt Institute promotes the safe use benefits and quality performance of petroleum asphalts in a unified voice for our membership. Design Criteria 21 Fatigue Cracking.

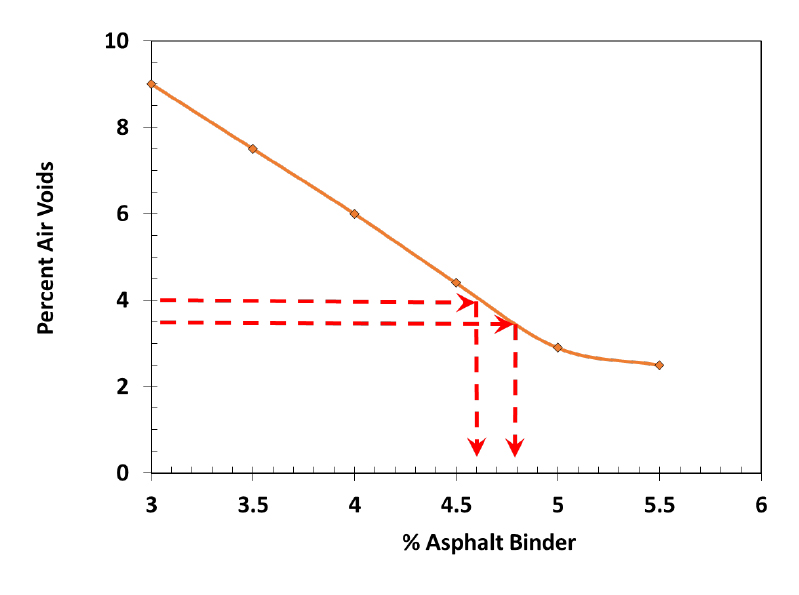

HMA mix design is the process of determining what aggregate to use what asphalt binder to use and what the optimum combination of these two ingredients should be.

Read another article:

The Asphalt Institute Design Method for Flexible Pavements. This method would be used by City and County Roadway Departments State Departments of Transportation. To expand on some of the recommendendations given in the manual regarding conditions not covered completely by the design procedure. 33 Outline of the Level 1 Volumetric Design Method The Superpave level 1 volumetric design method includes three principal parts. Use a dilution and application rate which will provide 01 to 03 gallon per square yard 31 dilution.

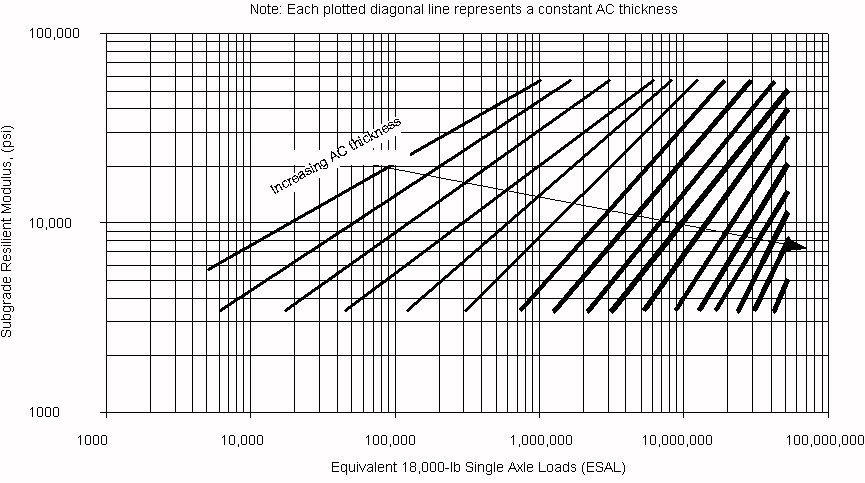

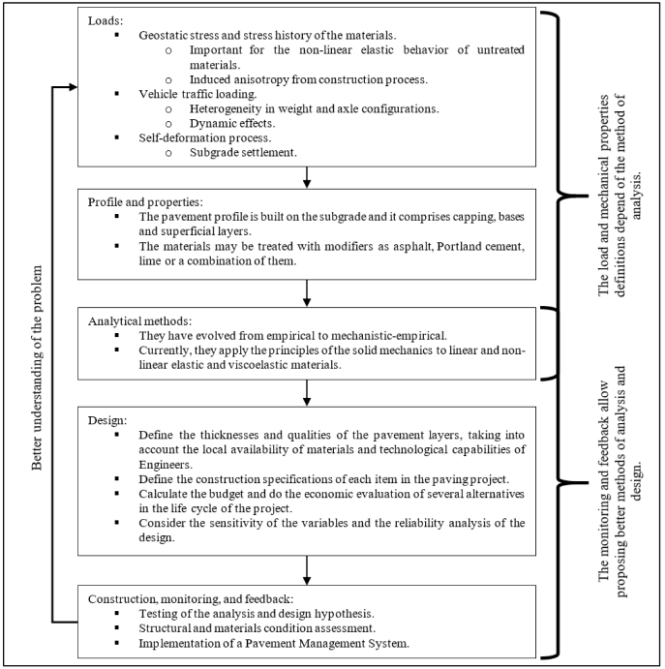

1 the potential of hot mix asphalt concrete HMAC mixture to permanently deform 2 flexural fatigue cracking potential 3 subgrade protection and 4 thermal cracking potential. SCOPE This model demonstrates a proposed method for designing testing and accepting hot mix asphalt mixes and pavements based on performance related criteria. The primary purposes of this publication are. The structural design of flexible pavements according to the Asphalt Institute Design Method is not practical to complete by hand. 2.

Source: semanticscholar.org

Source: semanticscholar.org

33 Outline of the Level 1 Volumetric Design Method The Superpave level 1 volumetric design method includes three principal parts. We evaluate the quality of the HMA by setting parameters on these three components which have historically provided a. B Emulsified asphalt surface. 2 selection of a design aggregate structure expressed as an aggregate gradation. Designing Cold Mix Asphalt Cma And Cold In Place Recycling Cir Using Superpave Gyratory Compactor Semantic Scholar.

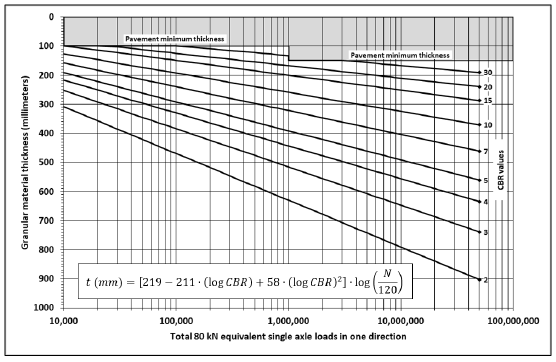

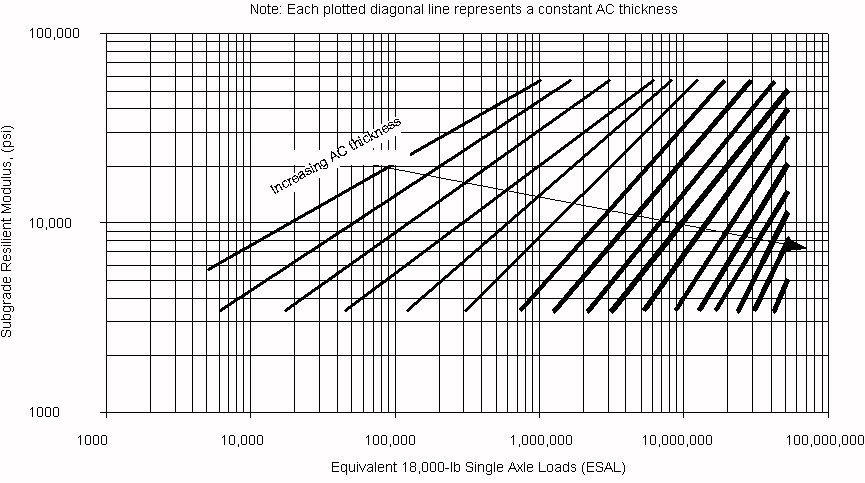

1 to decument the development of the Ninth Edition of the Asphalt Institute manual Thickness Design-Asphalt Pavements for Highways and Streets. 94 - 96 4 - 6 0. Development Topic 6 Asphalt Institute Design Procedure Two types of strains are considered critical in design of asphalt pavements. Each class is defined by the number of autos per day the average daily number of heavy trucks expected on the facility during the design period and the type of street or highway. 2.

Source: scielo.org.co

Source: scielo.org.co

Prepared by Rajesh Khadka acem. HMA mix design is the process of determining what aggregate to use what asphalt binder to use and what the optimum combination of these two ingredients should be. Traffic loading ESA Sub-grade resilient modulus Mr. The design procedure separates traffic into six classes I through VI. An Overview Of Asphalt Pavement Design For Streets And Roads.

Source: slidetodoc.com

Source: slidetodoc.com

Flexible Pavement Design Methods. And 3 selection of a design asphalt binder content. Design background AASHTO Procedure MechanisticEmpirical Procedures. MODEL PROCEDURE FOR PERFORMANCE BASED MIX DESIGN AND ACCEPTANCE OF HOT MIX ASPHALT 1. Flexible Pavement Thickness Design Asphalt Institute Method Source.

Source: researchgate.net

Source: researchgate.net

94 - 96 4 - 6 0. Prepared by Rajesh Khadka 21216. The Asphalt Institute Design Method for Flexible Pavements. Flexible Pavement Design Methods. Pdf An Overview Of Asphalt Pavement Design For Streets And Roads.

Source: slidetodoc.com

Source: slidetodoc.com

Prepared by Rajesh Khadka acem. To expand on some of the recommendendations given in the manual regarding conditions not covered completely by the design procedure. Determine the specific gravity of the aggregate combination and asphalt cement. You are required to design the pavement from Asphalt Institute Method. Flexible Pavement Thickness Design Asphalt Institute Method Source.

AI Method is used to design asphalt pavements composed of various combinations of. The CalME software includes the entire range of design methods used in California from the empirical procedure and a conventional mechanistic-empirical method based on the Asphalt Institute design criteria to a new recursive-incremental procedure with emphasis on the design of overlays based on the calibration of material properties from tests with heavy vehicle simulator HVS. AI Method is used to design asphalt pavements composed of various combinations of. 51 The procedure described in this practice is used to produce HMA which satisfies Superpave HMA volumetric mix design requirements. 2.

Source: youtube.com

Source: youtube.com

Design Methods Asphalt Mix 7th Edition MS-2 Asphalt Mix Design Methods 7th Edition. The purpose of this Guidance Note is to ensure that a. SCOPE This model demonstrates a proposed method for designing testing and accepting hot mix asphalt mixes and pavements based on performance related criteria. B Emulsified asphalt surface. Flexible Pavement Design Asphalt Institute Method Youtube.

Source: fhwa.dot.gov

Source: fhwa.dot.gov

1981 and Later Editions. And 3 selection of a design asphalt binder content. HMA mix design is the process of determining what aggregate to use what asphalt binder to use and what the optimum combination of these two ingredients should be. The CalME software includes the entire range of design methods used in California from the empirical procedure and a conventional mechanistic-empirical method based on the Asphalt Institute design criteria to a new recursive-incremental procedure with emphasis on the design of overlays based on the calibration of material properties from tests with heavy vehicle simulator HVS. Chapter 18 98042 Recycling Sustainability Pavements Federal Highway Administration.

Source: asphaltmagazine.com

Source: asphaltmagazine.com

Surface and base type 2. 114 STEPS OF DESIGN 1. This method would be used by City and County Roadway Departments State Departments of Transportation. 81 - 85 11 - 12 4 - 7. Ontario S First Experience With Regression Mix Design Method Asphalt Magazine.

Source: pavementinteractive.org

Source: pavementinteractive.org

Prepared by Rajesh Khadka acem. Good indication of a mixtures. 1981 and Later Editions. Prepare the trial specimens with varying asphalt contents. Component Analysis Asphalt Institute Pavement Interactive.

The Marshall mix design method can use any suitable method for estimating optimum asphalt content and usually relies on local procedures or experience. 1 selection of materials. Prepared by Rajesh Khadka acem. Flexible Pavement Design Methods. 2.

Source: scielo.org.co

Source: scielo.org.co

Flexible Pavement Design Methods. To expand on some of the recommendendations given in the manual regarding conditions not covered completely by the design procedure. The structural design of flexible pavements according to the Asphalt Institute Design Method is not practical to complete by hand. Use a dilution and application rate which will provide 01 to 03 gallon per square yard 31 dilution. An Overview Of Asphalt Pavement Design For Streets And Roads.

Source: studylib.net

Source: studylib.net

Incorporate an emulsion into the compaction water while placing the last 2 to 3 inches of the base course. Horizontal tensile strain εt the bottom of AC layer Vertical compressive stain εc the top of the subgrade 2. Prepared by Rajesh Khadka 21216. The CalME software includes the entire range of design methods used in California from the empirical procedure and a conventional mechanistic-empirical method based on the Asphalt Institute design criteria to a new recursive-incremental procedure with emphasis on the design of overlays based on the calibration of material properties from tests with heavy vehicle simulator HVS. Flexible Pavement Design Asphalt Institute Method Icivil Hu.