Pressure loss in the absence of more appropriate design experience at lower filtration rate can be 75 98 Pa as a typical data. Bag Filters in Boiler. Bag filter design for boiler

Bag Filter Design For Boiler, Along with choosing the filter type the designer must select the appropriatefiber typeFibers typically used include cotton nylon fiberglass Teflon Nomex Ryton etc. The pore volume varies between 7090. Bag Filter helps in separating the particulate matter from the flue gas coming out of the Steam Boiler. Pressure loss in the absence of more appropriate design experience at lower filtration rate can be 75 98 Pa as a typical data.

What Is Bag Filter A Bag Filter Is An Air Pollution By Thermodyne Boilers Medium From medium.com

What Is Bag Filter A Bag Filter Is An Air Pollution By Thermodyne Boilers Medium From medium.com

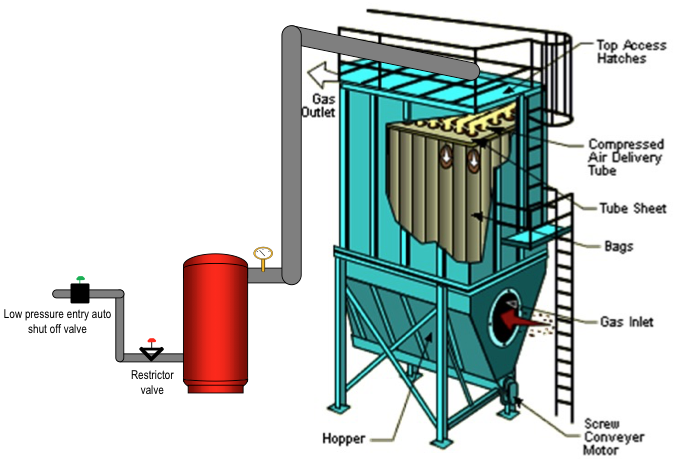

Pulse Jet Bag Filter Its Operation. The supporting vessel provides mechanical support for filters with high throughput rates and prevents the filter material from elongating. Pulse-jet cleaning bag Filter system utilise diaphragm valves to pass compressed air from the air supply lines and manifold into the blow piped within the bag filter. VS Envirocare Private Limited.

For turnkey solutions we will manage erectors controls engineers insulation contractors and other specialists to realise the total system on sites worldwide.

Read another article:

Think back to high school math and the circumference of a circle Therefore the circumference of the bags diameter of the bag x 314 multiplied by the length of the bag will. We design our filter bags for each customers specific application. The DUSTdown biomass filter. Pressure loss in the absence of more appropriate design experience at lower filtration rate can be 75 98 Pa as a typical data. Pulse-jet cleaning bag Filter system utilise diaphragm valves to pass compressed air from the air supply lines and manifold into the blow piped within the bag filter.

Source: techflow.net

Source: techflow.net

The air to media ratio is the most common design criteria discussed for filters. Bag filter comprises an arrangement of Bags made up of special fabric capable of bearing the operating temperature of up to 220 degree Celsius. However if taking a high filtration rate or the presence of viscous or low porosity of the dust layer should be taken slightly higher number. Tfi Filtration India Private Limited. All About Bag Filter.

Source: vortexeng.co.nz

Source: vortexeng.co.nz

That gas cloth than the filtration rate. Pulse Jet Bag Filter Its Operation. It is capable of handling 100 types of particulate matters. Bag Filters are air pollution controlling industrial equipment used prominently in a Steam Boiler House Assembly. Baghouse Filters Nz Baghouse Dust Collector.

Source: techflow.net

Source: techflow.net

The pore volume varies between 7090. Ad eBay Is Here For You with Money Back Guarantee and Easy Return. Our engineering team has 30 years of experience in surveying the output and needs of various plants and will study yours to find an appropriate solution to reach your desired emissions reductions. A Bag Filter is an air pollution controlling industrial equipment used prominently in a Steam Boile r House Assembly. Bag Filter For Boilers To Prevent Air Pollution.

Source: ph.parker.com

Source: ph.parker.com

The Dustdown is designed to reach very high efficiency levels. For turnkey solutions we will manage erectors controls engineers insulation contractors and other specialists to realise the total system on sites worldwide. The most common type of Bag Filter is Pulse jet type. The filtration process begins when ash-containing flue gas from a boiler is ducted into the lower portion of one of a number of baghouse compartments. Fulflo Sb Bag Filter Vessels Carbon Steel 304 316 Stainless Steel Asme Code Design For Process Liquid Filtration Parker Na.

Source: aqualine-me.com

Source: aqualine-me.com

However if taking a high filtration rate or the presence of viscous or low porosity of the dust layer should be taken slightly higher number. Pollution Control Bag Filter is an effective technology of gas steam filteration. These bags are long vertically fit upon a. The cages and bag or cartridge filters can either be bottom or top accessed. Mechanical Filters Aqualine Me.

Source: researchgate.net

Source: researchgate.net

To determine the appropriate filter size we must study the air-. There are different types of Bag Filters such as. Tfi Filtration India Private Limited. The filtration process begins when ash-containing flue gas from a boiler is ducted into the lower portion of one of a number of baghouse compartments. A Schematic Diagram Of The Pulse Jet Bag Filter Test Facility Download Scientific Diagram.

Source: sciencedirect.com

Source: sciencedirect.com

3outlet temperature of boiler apter aph- 180 degree c 4capacity of boiler- 12 tphfa 100 5desired spm- bag filter inlet- fly coal ash 7. For turnkey solutions we will manage erectors controls engineers insulation contractors and other specialists to realise the total system on sites worldwide. The cages and bag or cartridge filters can either be bottom or top accessed. Tfi Filtration India Private Limited. Pulse Jet Fabric Filter An Overview Sciencedirect Topics.

Source: cementequipment.org

Source: cementequipment.org

Stainless Steel Multi Round Bag Filter Housing For Industrial. Bag filters are normally made from needle punched nonwovens and act as depth filters. Respiratory protection for maintenance personnel may be required when replacing fabric. It is used to control the levels of sulfur dioxide and others. Bag Filter Design Infinity For Cement Equipment.

Source: indiamart.com

Source: indiamart.com

That gas cloth than the filtration rate. Fabric Filter gas cleaning systems Bag Filters Bag House comes in two variants Pulse Jet Bag Filter and Reverse Air Bag House catering to particulate emission control or product recovery in a boiler furnace kiln mill and material handling applications. Using a core team of trained and experienced professionals we design bespoke air filtration systems to suit your application. Air lock rotary for removal of dust from hopper. Bag Filter For Boilers Automation Grade Fully Automatic For Industrial Id 21054582733.

Source: techflow.net

Source: techflow.net

Heater for Dust hopper. Our experts at Techflow have years of experience in designing air pollution control systems for boiler operations. However if taking a high filtration rate or the presence of viscous or low porosity of the dust layer should be taken slightly higher number. The Bag Filter for boilers and flue gas provides an ulterior filtration of all sized particles and has higher dirt holding capacities. Bag Filter For Boilers Pollution Control Bag Filters.

Source: thermodyneboilers.com

Source: thermodyneboilers.com

The air to media ratio is the most common design criteria discussed for filters. It is capable of handling 100 types of particulate matters. Our engineering team has 30 years of experience in surveying the output and needs of various plants and will study yours to find an appropriate solution to reach your desired emissions reductions. Bag size- 1604000 mm. Air Pollution Control Equipment In Boilers Bag Filter Thermodyne Boilers.

Source: researchgate.net

Source: researchgate.net

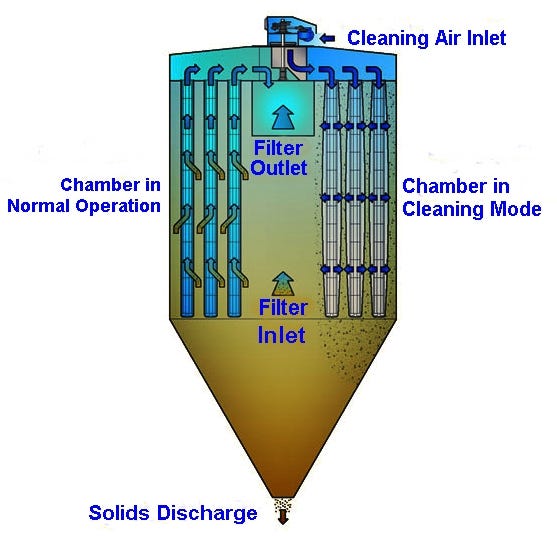

The DUSTdown biomass filter. Jagdamba Engineers Consultancy. To determine the appropriate filter size we must study the air-. Solenoid Valves are available in ¾ to 2 suitable for 24V DC and 110V230V AC. A Schematic Diagram Of Fabric Filter Download Scientific Diagram.

![]() Source: thermodyneboilers.com

Source: thermodyneboilers.com

The filtration process begins when ash-containing flue gas from a boiler is ducted into the lower portion of one of a number of baghouse compartments. Our experts at Techflow have years of experience in designing air pollution control systems for boiler operations. Compact Insertable Bag Filter. Collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector. Air Pollution Control Equipment In Boilers Bag Filter Thermodyne Boilers.

Source: rajdeepboiler.co.in

Source: rajdeepboiler.co.in

The supporting vessel provides mechanical support for filters with high throughput rates and prevents the filter material from elongating. Bag Filters in Boiler. The supporting vessel provides mechanical support for filters with high throughput rates and prevents the filter material from elongating. The air to media ratio is the most common design criteria discussed for filters. Bag Filter Rajdeep Boiler Pvt Ltd.

Source: airbestpractices.com

Source: airbestpractices.com

Ad eBay Is Here For You with Money Back Guarantee and Easy Return. VS Envirocare Private Limited. Fabric Filter gas cleaning systems Bag Filters Bag House comes in two variants Pulse Jet Bag Filter and Reverse Air Bag House catering to particulate emission control or product recovery in a boiler furnace kiln mill and material handling applications. The major components of the Bag house filter are- Bag house casing designed to withstand negative pressures upto 150 mm Wg. Maximizing Dust Collection System Efficiency Compressed Air Best Practices.