This paper presents the design of combustion chamber followed by. The most commonly known 4 steps for any internal combustion engine are as follows. Basic design principles for gas turbine combustor

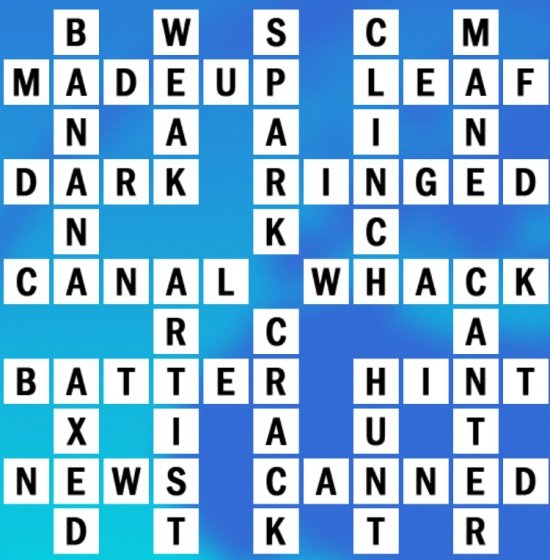

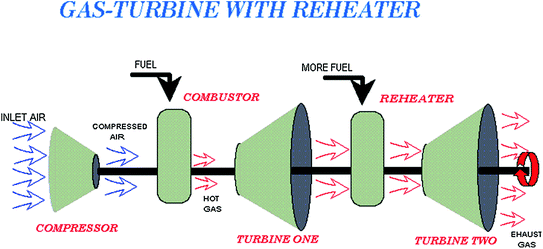

Basic Design Principles For Gas Turbine Combustor, 2 Gas Turbine Power Plants Gas turbines are thermodynamic systems that use fuel and air to produce a positive work transfer. The triangle on the left represents the compressor and the triangle on the right the turbine section. Gas Turbine Operating Principles. The basic principle on which a gas turbine works is similar to internal combustion reciprocating engine.

Gas Turbine Ethics And The Design Of Technology From sites.psu.edu

Gas Turbine Ethics And The Design Of Technology From sites.psu.edu

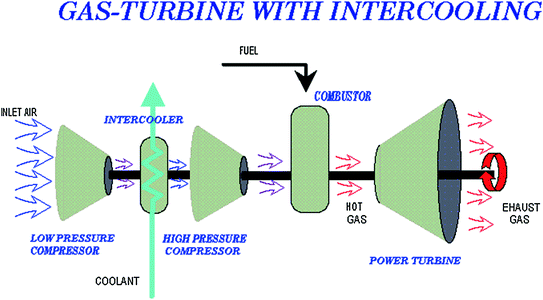

Proceedings of the 10 th ENCIT paper no0316. The idea is to provide information for producing designs that require minimum development time. A combustor is a component or area of engine where combustion takes place. Alstoms GT-8C2 5060Hz gas turbine with basic specification Table 1.

Both of these ideas with minor changes are the basis for most modern gas turbines in use today.

Read another article:

Marine Gas Turbine Engine Using a GTE to propel a ship goes back to 1937 when a Pescara free piston gas engine was used experimentally with a GTE. Of Mechanical Sciences and Engineering – ABCM Rio de Janeiro Brazil Nov. It is also known as a burner combustion chamber or flame holder. Also the pressure and temperature of fuel gas are monitored during normal operation of a Gas turbine. Gas Turbine Operating Principles.

Source: link.springer.com

Source: link.springer.com

In a gas turbine engine the combustor or combustion. A combustor is a component or area of engine where combustion takes place. The triangle on the left represents the compressor and the triangle on the right the turbine section. The combustor then heats this air at constant pressure. Gas Turbine Working Principles Springerlink.

Source: britannica.com

Source: britannica.com

The present work shows a methodology for gas turbine combustor basic design. Gas Turbine Operating Principles. Marine Gas Turbine Engine Using a GTE to propel a ship goes back to 1937 when a Pescara free piston gas engine was used experimentally with a GTE. The most commonly known 4 steps for any internal combustion engine are as follows. Gas Turbine Engine Britannica.

Source: link.springer.com

Source: link.springer.com

Many modern burners have an annular design. Gas turbine combustor design involves the calculation of parameters like gas mass flow rates pressure drops flame tube heat gains and losses annulus heat addition combustion equilibrium mixture compositions and temperatures. They convert the chemical potential energy of the fuel to mechanical energy. The resulting hot gas is allowed to expand. Gas Turbine Working Principles Springerlink.

Source: realpars.com

Source: realpars.com

The gas-turbine operates on the principle of the Brayton cycle where compressed air is mixed with fuel and burned under constant pressure conditions. Also the pressure and temperature of fuel gas are monitored during normal operation of a Gas turbine. Single shift machines. Alstom Power Table 1. What Is A Gas Turbine And How Does It Work For Beginners.

Source: sciencedirect.com

Source: sciencedirect.com

THE GAS TURBINE CYCLE The basic principle of the airplane turbine engine is identical to any and all engines that extract energy from chemical fuel. Single shift machines. Many modern burners have an annular design. Figure 3 below shows a gas turbine cutaway with its basic operating specification. Gas Turbine Combustion An Overview Sciencedirect Topics.

Source: sciencedirect.com

Source: sciencedirect.com

This chapter discusses design considerations in advanced gas-turbine combustion chambers. Of Mechanical Sciences and Engineering – ABCM Rio de Janeiro Brazil Nov. Basic design principles for gas turbine combustor in. The triangle on the left represents the compressor and the triangle on the right the turbine section. Gas Turbine Combustors An Overview Sciencedirect Topics.

Source: sites.psu.edu

Source: sites.psu.edu

Alstoms GT-8C2 5060Hz gas turbine with basic specification Table 1. The free piston engine or gasifier fig. In a gas turbine engine the combustor or combustion. 1-5 is a form of diesel engine. Gas Turbine Ethics And The Design Of Technology.

The burner in the middle is an older can or. There are three main types of combustors and all three designs are found in modern gas turbines. The basic geometry of a combustion chamber is largely dictated by the need to achieve efficient combustion with the minimum of pressure loss and at overall mixture strengths that lie well outside the inflammability limits of kerosine air mixtures. Chamber is fed high pressure air by the compression system. What Is The Working Principle Of Gas Turbine Engines Quora.

Source: powermag.com

Source: powermag.com

Both of these ideas with minor changes are the basis for most modern gas turbines in use today. THE GAS TURBINE CYCLE The basic principle of the airplane turbine engine is identical to any and all engines that extract energy from chemical fuel. The design and analysis of gas turbine combustion chamber is based on combined theoretical and empirical approach and the design of combustion chamber is a less than exact science. 2 Gas Turbine Power Plants Gas turbines are thermodynamic systems that use fuel and air to produce a positive work transfer. Flexible Turbine Operation Is Vital For A Robust Grid.

Source: sciencedirect.com

Source: sciencedirect.com

The basic principle on which the gas turbine works is identical to all the engines which is used to extract energy from the chemical fuel. Note this particular turbine model can be used for both 50 and 60Hz power generation. Combustion in the normal open cycle gas turbine is a continuous process in which fuel is burned in the air supplied by the compressor. The manufacturers need to know the details of fuel gas and only based on its characteristics they can guarantee the performance of their Gas turbines. Combustors An Overview Sciencedirect Topics.

Source: link.springer.com

Source: link.springer.com

Fuel gas is a key factor in the design and operation of a Gas turbine. Combustion of a liquid fuel involves the mixing of a fine spray of droplets with. Also the pressure and temperature of fuel gas are monitored during normal operation of a Gas turbine. They convert the chemical potential energy of the fuel to mechanical energy. Gas Turbine Working Principles Springerlink.

Source: semanticscholar.org

Source: semanticscholar.org

The burner in the middle is an older can or. A combustor is a component or area of engine where combustion takes place. The resulting hot gas is allowed to expand. The most commonly known 4 steps for any internal combustion engine are as follows. Pdf Preliminary Design Program Development For Aircraft Gas Turbine Combustors Part 2 Air Flow Distribution Semantic Scholar.

Source: mechanicalboost.com

Source: mechanicalboost.com

Figure 3 below shows a gas turbine cutaway with its basic operating specification. The design and analysis of gas turbine combustion chamber is based on combined theoretical and empirical approach and the design of combustion chamber is a less than exact science. An electric spark is required only for initiating the combustion process and thereafter the flame must be self-sustaining. Chamber is fed high pressure air by the compression system. Gas Turbine Working Principle Main Components And Types.

Source: sciencedirect.com

Source: sciencedirect.com

Proceedings of the 10 th ENCIT paper no0316. Proceedings of the 10 th ENCIT paper no0316. The basic geometry of a combustion chamber is largely dictated by the need to achieve efficient combustion with the minimum of pressure loss and at overall mixture strengths that lie well outside the inflammability limits of kerosine air mixtures. The combustor then heats this air at constant pressure. Industrial Gas Turbine An Overview Sciencedirect Topics.

Source: researchgate.net

Source: researchgate.net

Base load at ISO conditions Source. There are three main types of combustors and all three designs are found in modern gas turbines. The burner in the middle is an older can or. In a gas turbine engine the combustor or combustion. 7 Gas Turbine Aero Engine Courtesy Of General Electric Jet Engine Download Scientific Diagram.