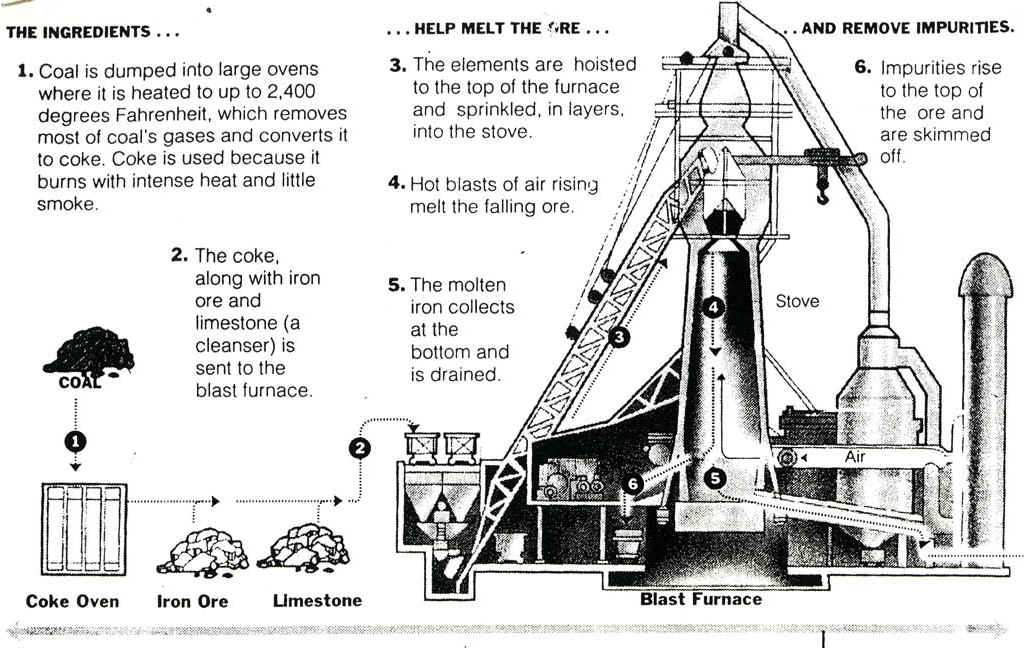

BFs operated at Jamshedpur works modification of trough design in the upgraded G-BF and its performance and details of improvements made in the trough back-up refractory lining its wear monitoring and cooling systems. Step 2b - the Blast Furnace The inner lining is made of insulating bricks designed to reduce heat loss through the outer walls of the furnace. Blast furnace trough design

Blast Furnace Trough Design, Blast Furnace Zones and Charging Systems. Alumina components Volume stability Wear resistance. The hot blast temperature can be from 1600F to 2300F depending on the stove design and condition. Blast Furnace Trough Mix Refractory Material.

Blast Furnace An Overview Sciencedirect Topics From sciencedirect.com

Blast Furnace An Overview Sciencedirect Topics From sciencedirect.com

An extensive range of refractories ideal for use downstream of the blast furnace is also available including. 2 blast furnace is a single taphole furnace with a convection air-cooled iron trough. The Caspian region may also have been the source for the. Step 2a - the Blast Furnace The sinter is added through a hopper at the top of the Blast Furnace.

The hot blast temperature can be from 1600F to 2300F depending on the stove design and condition.

Read another article:

Through it with the flow trough the hot stove into the mixing chamber just before the. A blast furnace is a block that smelts ores raw metals iron and gold armor and tools similar to a furnace but at twice the rate. The Caspian region may also have been the source for the. The hot blast temperature can be from 1600F to 2300F depending on the stove design and condition. The corrosionerosion in the main trough is caused by the turbulent mix of metal and slag.

Source: researchgate.net

Source: researchgate.net

An extensive range of refractories ideal for use downstream of the blast furnace is also available including. Blast Furnace Zones and Charging Systems. The effect of a wear pattern in the blast furnace trough has been also re- change in the trough lining profile due to refractory wear on ported in literature14 Though a. Blast Furnace Trough Mix Refractory Material Role Alumina components Volume stability Wear resistance Silicon Carbide SiC Wear resistance Oxidation. Schematic View Of Blast Furnace Download Scientific Diagram.

Source: pinterest.com

Source: pinterest.com

As the BF production increased due to many design improvements removal of liquid products iron and slag became an issue. A blast furnace is a type of metallurgical furnace used for. Blast Furnace Trough Mix Refractory Material Role Alumina components Volume stability Wear resistance Silicon Carbide SiC Wear resistance Oxidation. Download Principles Of Blast Furnace Iron Making By A K Biswas Book For Free in PDF. Photograph Of The Blast Furnace At Republic Steel 1940 I Digitized This Photograph As Part Of My Practicum At Clevelan Architektur Verlassene Orte Ruhrgebiet.

Source: semanticscholar.org

Source: semanticscholar.org

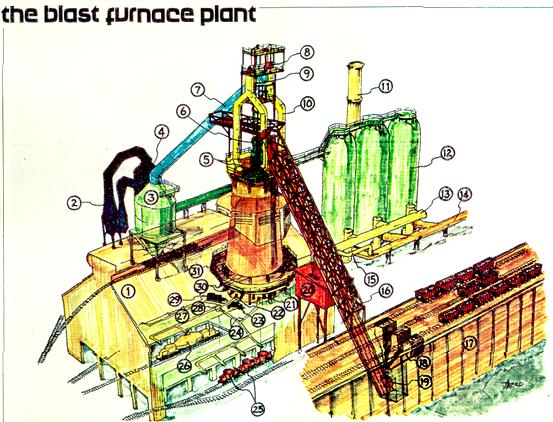

Major of these equipments are top charging equipment cast house equipment clay guns tap hole drills trough cover manipulators tilting runners for iron and slag bar changers and jack dam drills etc tuyere stocks various type of valves. Once a taphole is drilled through the refractory clay plug liquid iron and slag flow down a trough through a skimmer opening. Major of these equipments are top charging equipment cast house equipment clay guns tap hole drills trough cover manipulators tilting runners for iron and slag bar changers and jack dam drills etc tuyere stocks various type of valves. Cameron and Tudhopet although is directed towards the design of a better trough does not reflect on the wear of the trough bed near the iron dam. Flow Characteristics In A Blast Furnace Trough Semantic Scholar.

Source: sciencedirect.com

Source: sciencedirect.com

High quality tap hole mixes customized to meet customer requirements. Trough cover manipulators. Blast furnace profile and dimensionsThe BF profile. Major of these equipments are top charging equipment cast house equipment clay guns tap hole drills trough cover manipulators tilting runners for iron and slag bar changers and jack dam drills etc tuyere stocks various type of valves. Blast Furnace An Overview Sciencedirect Topics.

Source: nl.pinterest.com

Source: nl.pinterest.com

A blast furnace can be picked up by any pickaxe. Blast Furnace Trough Mix Refractory Material. And geometrical design of the trough Theresults indicate that at constant physical properties the flow veocity in the upper stream of the trough is the predominant factor in determining the. DASH and SATISH K. Paradise Furnace In The Trough Creek State Park Just East Of State Rt 994 On The South Eastern Edge Of Raystown Lake H Iron Furnace State Parks Huntingdon.

Source: sciencedirect.com

Source: sciencedirect.com

This heated air then exits. Blast furnace gas is produced during the iron oxide reduction in blast furnace iron making in which iron ore. Through it with the flow trough the hot stove into the mixing chamber just before the. A blast furnace trough and liner for transferring molten metal from a blast furnace or the like to a hot metal runner or the like comprises a metal trough with an expendable one-piece prefabricated liner therein the liner being formed of refractory based materials in several layers of different densities coalesced by physical force in the form of vibratory motion applied thereto. Blast Furnace An Overview Sciencedirect Topics.

Source: pinterest.com

Source: pinterest.com

Blast Furnace Trough Mix Refractory Material. Alloy steel 2 Belly 1 BF 1 BF Taphole 1 BF Trough 2 Blast Furnace 5. 22 Design Aspects of Main Trough based on Blast Furnace Operation Parameters Main trough contributes more that 50 of the total specific consumption value in any trough management. AJMANI Research and Development Division Jamshedpur - 831007 India. 1743 Steam Engine Used For Blast Furnace Bellows Industrial Revolution Wellness Design Design.

Source: project.geo.msu.edu

Source: project.geo.msu.edu

Blast Furnace Design Zones and arrangements for Ironmaking 19-July-2009. Cameron and Tudhopet although is directed towards the design of a better trough does not reflect on the wear of the trough bed near the iron dam. The purpose of a blast furnace is to chemically reduce and. Blast furnace gas is produced during the iron oxide reduction in blast furnace iron making in which iron ore. Steel Mill.

Source: researchgate.net

Source: researchgate.net

It is in- parison with those for the standard trough design. Byusing awater-oil physical modelof the blast furnace trough the flow behavior andthe separation efficiency in the trough were investigated. This heated air then exits. Blast Furnace Zones and Charging Systems. The Blast Furnace Process Download Scientific Diagram.

Source: thepotteries.org

Source: thepotteries.org

Design Brandays Designworks. High quality tap hole mixes customized to meet customer requirements. Once a taphole is drilled through the refractory clay plug liquid iron and slag flow down a trough through a skimmer opening. Removable covers can be lifted and moved by hydraulic manipulators opening access for taphole machines. The Blast Furnace.

Source: sciencedirect.com

Source: sciencedirect.com

Blast Furnace 3 with the 31 minutes of blast time at the top left and blast temperature. The important parameters of the geometry would be - length. The Caspian region may also have been the source for the. 172 Blast furnace design and facilities1721. Blast Furnace An Overview Sciencedirect Topics.

Source: ar.pinterest.com

Source: ar.pinterest.com

Blast Furnace Design Zones and arrangements for Ironmaking 19-July-2009. High quality tap hole mixes customized to meet customer requirements Concretes with excellent performance characteristics ideal for troughs and runners. DASH and SATISH K. Set across and into the trough is a block of refractory called a skimmer which has a small opening underneath. Cool To The Touch Eiffel Tower Inside Cool Stuff Monongahela.

Source: pinterest.com

Source: pinterest.com

Blast Furnace Zones and Charging Systems. Major of these equipments are top charging equipment cast house equipment clay guns tap hole drills trough cover manipulators tilting runners for iron and slag bar changers and jack dam drills etc tuyere stocks various type of valves. Alumina components Volume stability Wear resistance. Blast Furnace Trough Mix Refractory Material. Love This Idea Of Old Hot Water Heater Turned Into Planters Garden Planters Diy Water Heater Diy Planters.

Source:

Source:

Blast furnaces will survive into the 2000 millennium because the larger efficient. Once a taphole is drilled through the refractory clay plug liquid iron and slag flow down a trough through a skimmer opening. 2 blast furnace is a single taphole furnace with a convection air-cooled iron trough. Blast furnace gas is produced during the iron oxide reduction in blast furnace iron making in which iron ore. Cgfxqgmboyqywm.

Source: thepotteries.org

Source: thepotteries.org

Alloy steel 2 Belly 1 BF 1 BF Taphole 1 BF Trough 2 Blast Furnace 5. Step 2b - the Blast Furnace The inner lining is made of insulating bricks designed to reduce heat loss through the outer walls of the furnace. Blast Furnace Trough Mix Refractory Material Role Alumina components Volume stability Wear resistance Silicon Carbide SiC Wear resistance Oxidation. The trough design is based on fluid flow characteristics along with thermo-chemical reactions. The Blast Furnace.