DSM screens or sieve bends are a fixed screen commonly used for dewatering. 120 DSM Screen Pulp thickening recovery and separation of fibers. Dsm screen design.

Dsm Screen Design, DSM screens are also known as sieve bends after Dutch State Mines who introduced the sieve bend as a static sizing screen having ten times greater capacity than conventional vibrating screens. Use at height limit. 120 DSM Screen Pulp thickening recovery and separation of fibers. For example 2 wirecloth has a much higher basic capacity than 14 wirecloth.

Sieve Bend Screen Dsm Screen For Dewatering Separating From wedgewire-screen.com

Sieve Bend Screen Dsm Screen For Dewatering Separating From wedgewire-screen.com

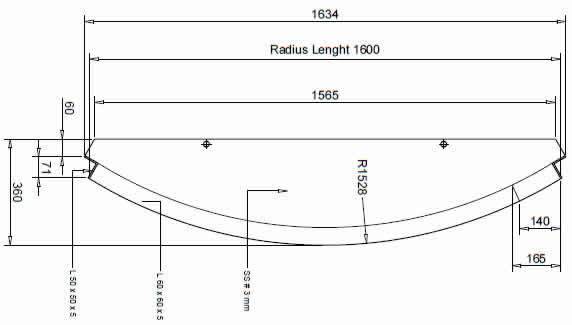

Come work with us. Its a striking way to grab attention - provided. 800 mm arc length Media recovery. 1600 mm arc length Made for maximum drainage.

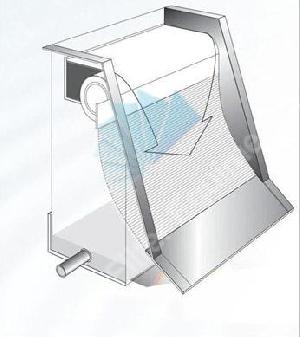

The screen is fed from the top with slurry where the slope is practically vertical while the deck changes in an elliptical fashion such the discharge is almost horizontal.

Read another article:

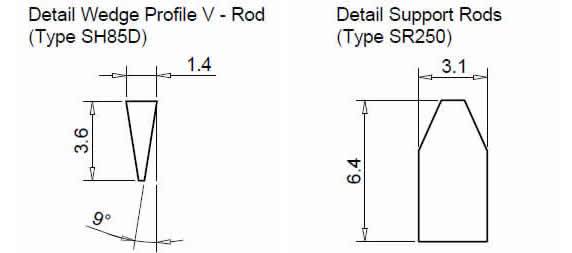

DSM screen to separate plastic flake - 38 from water containing fiber and floating material. Each design example uses the same cross-section in this case C-section 9CS25x059. DSM screen 1830 1600 mm hole 07 mm. However they can also be designed in the form of. It depends on the wirecloth opening size and design of the screen.

The common DSM screen available types are 45 60 120 270 300. DSM Screen is short of Dutch State Mines Screen. Design examples provided in Chapter 8. Its a striking way to grab attention - provided. 2.

Source: exportersindia.com

Source: exportersindia.com

Design examples provided in Chapter 8. High Capacity Non-Clogging No Moving Parts Stainless Steel Wedge Wire Screen Low Space Requirement Mild Steel Housing Gravity Feed 60 Slope Adjust Flow Wier OPTIONS. 122-6 Mnl Mne if λl. Design examples provided in Chapter 8. Dsm Screen And Raw Juice Dsm Screen Buy Dsm Screen Raw Juice Dsm Screen.

Source: wirescreen.org

Source: wirescreen.org

Every wedge wire sieve bend screen DSM screen is taken seriously every customer is God every enthusiasm will not be disappointed. Flexible Design - we can supply units with any features you may require. DSM Screen also known as side hill screens parabolic screens run down screens gravity screens and Sieve Bend Screen Sieve Bend Screens can be custom designed to separate solids from liquids in various applications including food processing pulp and paper waste water cleanup surface water intakes corn wet milling coal preparation and gold recovery. Each topic is displayed for a few seconds sometimes with a short video to spice things up. New Type Of Dsm Screen.

Source: wedgewire.org

Source: wedgewire.org

Each design example uses the same cross-section in this case C-section 9CS25x059. Some DSM sites have TV screens in public areas reception the canteen etc showing continuously rotating DSM content sometimes broadcast via narrowcasting ie specific content for a specific site. 1200 mm arc length Maximum drainage but the height does not allow 1600 mm. McLanahan enhanced this design using a crossbeam structure that makes the machine more robust and easier to maintain. Dsm Screens For Sugar Is Also Known As Sieve Bend Screen And Mainly Used For Liquid Solid Separation.

Source: wedgewire-screen.com

Source: wedgewire-screen.com

September 24 2021 Sieve Bend Screen DSM Screen is a small non-power separation device used to filter suspended floating sediment and other substances in sewage treatment. These screens are mainly used for liquid solid separation and manufactured to suit a wide range of industries such as. Pulp Paper. The sieve bend or DSM screen is an important and effective solution in size classification and dewatering fine particle slurries in heavy minerals processing applications. Sieve Bend Screen Dsm Screen For Dewatering Separating.

Source: wirescreen.org

Source: wirescreen.org

It is a curved concave wedge bar type of stationary screen. Basic capacities depend greatly on the design of the screen and most capacity formulas. It depends on the wirecloth opening size and design of the screen. 120 DSM Screen Pulp thickening recovery and separation of fibers. New Type Of Dsm Screen.

Source: wedgewire.org

Source: wedgewire.org

We specialize in screen printing logos and t-shirt designs. DSM screen mesh for sugar industry size 2400 1600 06 mm. Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools. Sieve Bend Screens are ideal for sizing and de-watering applications to remove solids from liquids or in solidsolid separation for dry feed situations. Dsm Screens Is Also Named Sieve Bend Screen Made Of Profile Wire And Screens Using In Sugar Mill Paper Mining.

Source: meshfiltro.com

Source: meshfiltro.com

Sieve bends do not require power to operate unless a tilting system is integrated and are a low-cost quiet and efficient part of your screening process. Flexible Design - we can supply units with any features you may require. Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools. The MiScreen system eliminates all the time consuming process of creating carbon based artwork for Thermal-Copier GOCCO models printing artwork films or generating artwork onto another format before its transferred onto the screen mesh. Johnson Screens Sieve Bend Manufacturer Dsm Dewatering Screens.

Source: exportersindia.com

Source: exportersindia.com

The sieve bend or DSM screen is an important and effective solution in size classification and dewatering fine particle slurries in heavy minerals processing applications. The Sieve Bend is also known as a DSM Screen after the Dutch State Mines introduced the product. Commonly DSM screens are usually flat or curved. With no moving parts these screens require minimal maintenance. Dsm Screen And Raw Juice Dsm Screen Buy Dsm Screen Raw Juice Dsm Screen.

Source: aqseptence.com

Source: aqseptence.com

Flexible Design - we can supply units with any features you may require. Flexible Design - we can supply units with any features you may require. We specialize in screen printing logos and t-shirt designs. DSM SCREEN INDUSTRY USES. Johnson Screens Water Treatment Screens.

Source: wirescreen.org

Source: wirescreen.org

Long lasting ppolyurethane panels or stainless steel wire. DSM Curved Flat Screen. Flexible Design - we can supply units with any features you may require. Feed to the screen 5 HDPE flake in water. New Type Of Dsm Screen.

![]() Source: meshfiltro.com

Source: meshfiltro.com

DSM Curved Flat Screen. With no moving parts these screens require minimal maintenance. DSM Screen also known as side hill screens parabolic screens run down screens gravity screens and Sieve Bend Screen Sieve Bend Screens can be custom designed to separate solids from liquids in various applications including food processing pulp and paper waste water cleanup surface water intakes corn wet milling coal preparation and gold recovery. September 24 2021 Sieve Bend Screen DSM Screen is a small non-power separation device used to filter suspended floating sediment and other substances in sewage treatment. Johnson Screens Sieve Bend Manufacturer Dsm Dewatering Screens.

Source: wedgewire.org

Source: wedgewire.org

Basic capacities depend greatly on the design of the screen and most capacity formulas. Sieve Bend Screens can be manufactured in a variety of widths arc lengths apertures or wedge wires. DSM screens are also known as sieve bends after Dutch State Mines who introduced the sieve bend as a static sizing screen having ten times greater capacity than conventional vibrating screens. The MiScreen system eliminates all the time consuming process of creating carbon based artwork for Thermal-Copier GOCCO models printing artwork films or generating artwork onto another format before its transferred onto the screen mesh. Dsm Screens Is Also Named Sieve Bend Screen Made Of Profile Wire And Screens Using In Sugar Mill Paper Mining.

Source: cp-screens.com

Source: cp-screens.com

Rigid screen box frame construction Optional Timed Vibra motors. The sieve bend or DSM screen is an important and effective solution in size classification and dewatering fine particle slurries in heavy minerals processing applications. Sieve bends do not require power to operate unless a tilting system is integrated and are a low-cost quiet and efficient part of your screening process. It is also referred to sieve bend screen. Sieve Bend Screen 120 Deg Dsm Cp Screens.

Source: wedgetech.com.au

Source: wedgetech.com.au

It depends on the wirecloth opening size and design of the screen. Coal Mining Quarrying. High Capacity Non-Clogging No Moving Parts Stainless Steel Wedge Wire Screen Low Space Requirement Mild Steel Housing Gravity Feed 60 Slope Adjust Flow Wier OPTIONS. Go to DSM Sieve Assemblies DSM Sieve Assemblies. Dsm Sieve Bend Assemblies Curved Screens Wedge Tech Australia.